Advanced Filtration Technologies for Compressed Air and Industrial Fluids

03/25/2025

In industrial settings, the purity of compressed air and process fluids is paramount. Contaminants, ranging from microscopic particles to unwanted moisture and microorganisms, can wreak havoc on equipment, compromise product quality, and increase operating costs. Advanced filtration technologies are essential for removing these impurities, ensuring optimal system performance and protecting valuable assets. This post explores the critical role of filtration in industrial applications, delves into various cutting-edge filtration technologies, and highlights how Blackhawk Equipment can help you implement the right solutions for your specific needs.

Contaminants in Compressed Air and Industrial Fluids

The types of contaminants present in compressed air and industrial fluids vary depending on the application and environment, but some common culprits include:

Compressed Air:

-

Particulates: Dust, dirt, rust, pipe scale, and other solid particles can damage downstream equipment and contaminate products.

-

Water (Liquid and Vapor): Moisture in compressed air can lead to corrosion, equipment malfunction, and microbial growth.

-

Oil (Aerosols and Vapor): Oil carryover from lubricated compressors can contaminate processes and products, particularly in applications requiring oil-free air.

-

Microorganisms: Bacteria and viruses can proliferate in compressed air systems, posing a risk in sensitive applications like food and beverage processing and pharmaceuticals.

Industrial Fluids (e.g., hydraulic oil, lubricating oil, process water, coolants):

-

Particulates: Metal shavings, wear debris, dirt, and other solid particles can cause abrasion and damage to equipment components.

-

Water: Water contamination in hydraulic and lubricating oils can lead to corrosion, reduced lubricity, and component failure.

-

Microorganisms: Bacteria and fungi can grow in industrial fluids, causing fouling, degradation, and potential health hazards.

-

Degradation Products: Over time, industrial fluids can break down, forming sludge, varnish, and other undesirable byproducts that can impair system performance.

-

Air and Gases: Air can cause cavitation and reduce efficiency.

Types of Filtration Technologies

A variety of filtration technologies are available to address the specific challenges of different contaminants and applications:

Compressed Air Filters:

-

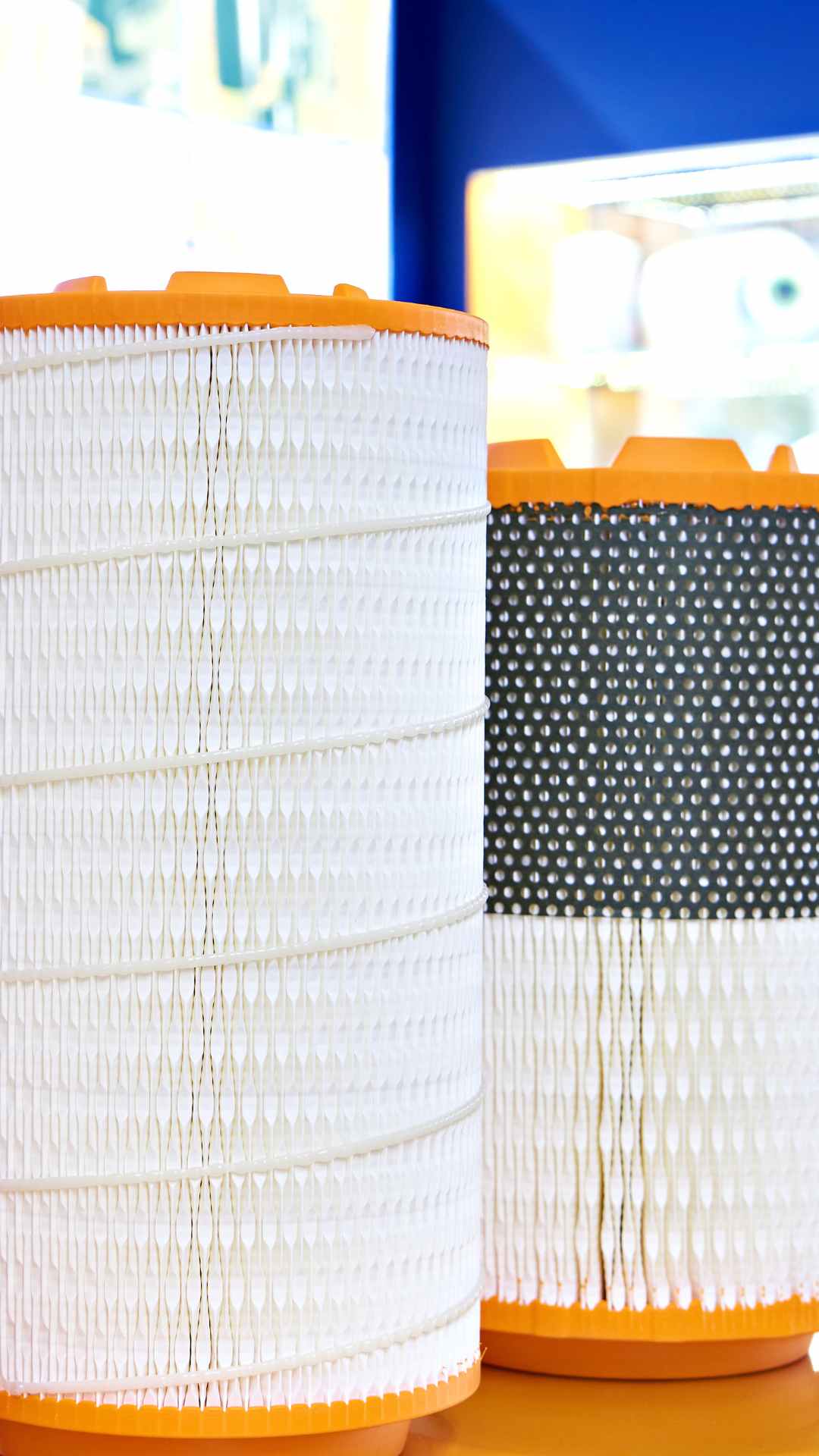

Particulate Filters: These filters remove solid particles using various media, such as pleated paper, cellulose, or synthetic fibers. They are rated based on their particle removal efficiency (e.g., 0.01 micron).

-

Coalescing Filters: These filters are specifically designed to remove oil aerosols and water droplets. They work by forcing the air through a dense fiber matrix, causing the small droplets to coalesce into larger drops that can be drained away.

-

Activated Carbon Filters: These filters use activated carbon to adsorb oil vapor and odors from compressed air. They are often used downstream of coalescing filters to provide extremely clean air.

-

Sterile Air Filters: These filters are designed to remove bacteria and viruses from compressed air, typically using a membrane with very small pore sizes (e.g., 0.2 micron). They are essential for applications requiring sterile air, such as food and beverage processing, pharmaceuticals, and healthcare.

Industrial Fluid Filters:

-

Strainers: These are coarse filters that remove large particles and debris, typically used as a pre-filter to protect pumps and other equipment.

-

Bag Filters: These filters use a disposable filter bag made of various materials (e.g., felt, mesh) to remove particles. They offer a good balance of cost-effectiveness and filtration efficiency.

-

Cartridge Filters: These filters use a replaceable cartridge containing a filter medium (e.g., pleated paper, melt-blown polypropylene, membrane) to remove particles. They offer higher efficiency and dirt-holding capacity than bag filters.

-

Self-Cleaning Filters: These filters automatically clean the filter element, reducing maintenance requirements. They are often used in applications with high contaminant loads.

-

Centrifugal Separators: Remove water and particulate by spinning the fluid.

-

Vacuum Dehydration: Remove water, air and particulate.

Advanced Filtration Technologies

Beyond traditional filtration methods, several advanced technologies are emerging:

-

Nanofiber Filtration: Nanofiber media, with fibers that are orders of magnitude smaller than traditional fibers, offer significant advantages:

-

Higher Efficiency: Capture smaller particles with lower pressure drop.

-

Increased Dirt-Holding Capacity: Longer filter life and reduced maintenance.

-

Lower Energy Consumption: Reduced pressure drop translates to lower energy consumption for compressors and pumps.

-

-

Membrane Filtration: Membrane filters, with precisely controlled pore sizes, can achieve very high levels of purity, removing even the smallest particles and microorganisms. They are commonly used in sterile air applications and for producing ultra-pure water.

-

Microfiltration: Removes particles in the 0.1 to 10 micron range.

-

Ultrafiltration: Removes particles in the 0.01 to 0.1 micron range, including some viruses.

-

Nanofiltration: Removes particles in the 0.001 to 0.01 micron range, including dissolved salts.

-

Reverse Osmosis: Removes virtually all dissolved solids and microorganisms.

-

-

Electrostatic Filtration: Electrostatic precipitators use an electric charge to attract and capture particles from an air or gas stream. They are particularly effective at removing fine particles and smoke

.

.

Selecting the Right Filtration System

Choosing the appropriate filtration system requires careful consideration of several factors:

-

Application Requirements: What level of purity is required for the specific application?

-

Contaminant Type and Size: What types of contaminants need to be removed, and what are their sizes?

-

Flow Rate: What is the volume of air or fluid that needs to be filtered per unit of time?

-

Pressure Drop: How much pressure drop can the system tolerate? Excessive pressure drop increases energy consumption.

-

Maintenance Requirements: How often will filters need to be replaced or cleaned?

-

Operating Costs: Consider the initial cost of the system, as well as the ongoing costs of filter replacements and energy consumption.

-

Fluid Viscosity: Thicker fluids require different filtration.

Blackhawk Equipment's Filtration Solutions

Blackhawk Equipment offers a comprehensive range of filtration solutions for compressed air and industrial fluids. We partner with leading manufacturers to provide our customers with the latest technologies and the highest quality products. Our expertise includes:

-

System Design: We can design custom filtration systems tailored to your specific needs and application requirements.

-

Product Selection: We offer a wide selection of filters, including particulate filters, coalescing filters, activated carbon filters, sterile air filters, bag filters, cartridge filters, and self-cleaning filters.

-

Installation and Service: We provide professional installation and ongoing maintenance services to ensure optimal performance and long filter life.

-

Air Quality Testing: We can conduct air quality testing to determine the level of contamination and recommend the appropriate filtration solution.

Conclusion

Advanced filtration technologies are essential for protecting equipment, ensuring product quality, and improving efficiency in industrial applications. By understanding the different types of contaminants, filtration methods, and selection criteria, engineers can make informed decisions about their filtration needs. Blackhawk Equipment is your trusted partner in implementing these solutions.

Contact Blackhawk Equipment today for a filtration consultation and discover how we can help you achieve the highest levels of purity and performance in your compressed air and industrial fluid systems. Let us help you protect your valuable assets and optimize your operations with advanced filtration technology.