INDUSTRIAL FLUID PUMPS

Fluid pumps or industrial pumps are designed specifically to be used in harsh application areas. They move various materials, such as heavy chemical fluids, food, water, oil, petroleum, sludges, slurries, waste and even beer.

Every different type of commercial or industrial process might demand a separate fluid pump setup. Thus, you must use the correct type of fluid pump to handle the tasks with optimum energy efficiency, minimum downtime, and fluid contamination.

There are many fluid pump types available on the market, each with its own weaknesses and strengths. So, failing to choose the right pump can cause inefficient operations and, worse, equipment failures, safety issues and product loss.

So, it's essential to ensure that you have expert manufacturers who provide the best guidance on choosing the right products per your requirements. When it comes to selecting suitable fluid pumps, we've got you covered! Blackhawk most often recommends Grundfos Fluid Pumps based on their impressive service record and performance.

Contact Blackhawk Equipment for technical advice and premium industrial fluid pumps today.

Grundfos Fluid Pumps Overview

Efficient and Energy-Saving Fluid Pumps from Grundfos

Focusing on energy efficiency is a crucial aspect of running any business and one of the hottest industry topics facing all teams. Energy costs directly impact the overall product output, no matter which industry you are based in.

One critical factor that plays a vital role in deciding the plant's overall energy efficiency is the optimum efficiency of your fluid pumps. The efficiency of pumps is defined as the ratio of the pump's output power to its input power. The output power refers to the amount of work the pump does, whereas the input power is the amount of energy the pump consumes to give that output. The less energy it uses, the higher the efficiency of the pump. Optimizing energy efficiency is crucial as it reduces the cost of the pump at which it operates and its environmental impact. The pump's efficiency is based on several factors, such as:

- Physical properties of the fluids being pumped

- The design and materials of the pump

- Outside operating conditions of the pump's location

- Drive system that powers the pump

- The height of the suction lift

Furthermore, selecting newer models of fluid pumps is usually a better choice as they are equipped with the latest technology that helps them operate with less energy. Keeping the pumps lubricated and regularly checking the alignment also helps save energy. Also, keep your pump area clean and free of debris, as it will ensure the proper airflow required for energy-efficient pump operation.

Choosing pump manufacturers with a track record of providing energy-efficient pumps is always the best. This is why Blackhawk Equipment recommends Grundfos most often. A slight fluctuation in energy efficiency can cause a significant loss in your production. Therefore, always keep a pump's energy efficiency in mind whenever you procure new pumps and always buy from a reliable pump manufacturer that provides premium quality and energy-efficient pumps like Grundfos.

Contact Blackhawk Equipment for all your fluid pump requirements, and we will ensure you get the best quality pump per your needs and requirements. Below here are some of the most common types of fluid pumps from Grundfos.

Fluid Pumps for Every Application

Industrial fluid pumps can be used across a wide array of industries, such as automotive, oil and gas, brewing, extraction, medical, mining, food and beverage, and power.

Blackhawk Equipment excels at selling, designing, and installing fluid pumps for every application. Most industry types use centrifugal pumps, reciprocating pumps, or rotary pumps. We at Blackhawk Equipment have repeatedly proven ourselves by delivering quality pumps in each category. With us, your business production will run smoothly 24/7 without any interruption. Also, you will save money, energy, and time. Whether you are dealing with corrosive, toxic, or abrasive industrial liquids, our company can install a Grundfos pump that can efficiently tackle the toughest tasks.

In Line Single Stage Pumps

Includes PACO and Peerless brand pumps for process and water utility markets. Available in vertical and horizontal configurations and split case and end suction. Grundfos TP, TPE pumps are single-stage, close-coupled in-line centrifugal pumps with mechanical shaft seal and for applications such as heating/cooling/district energy/hot water recirculation. The pumps are with either fixed speed motors (TP/TPD) or speed controlled motors.

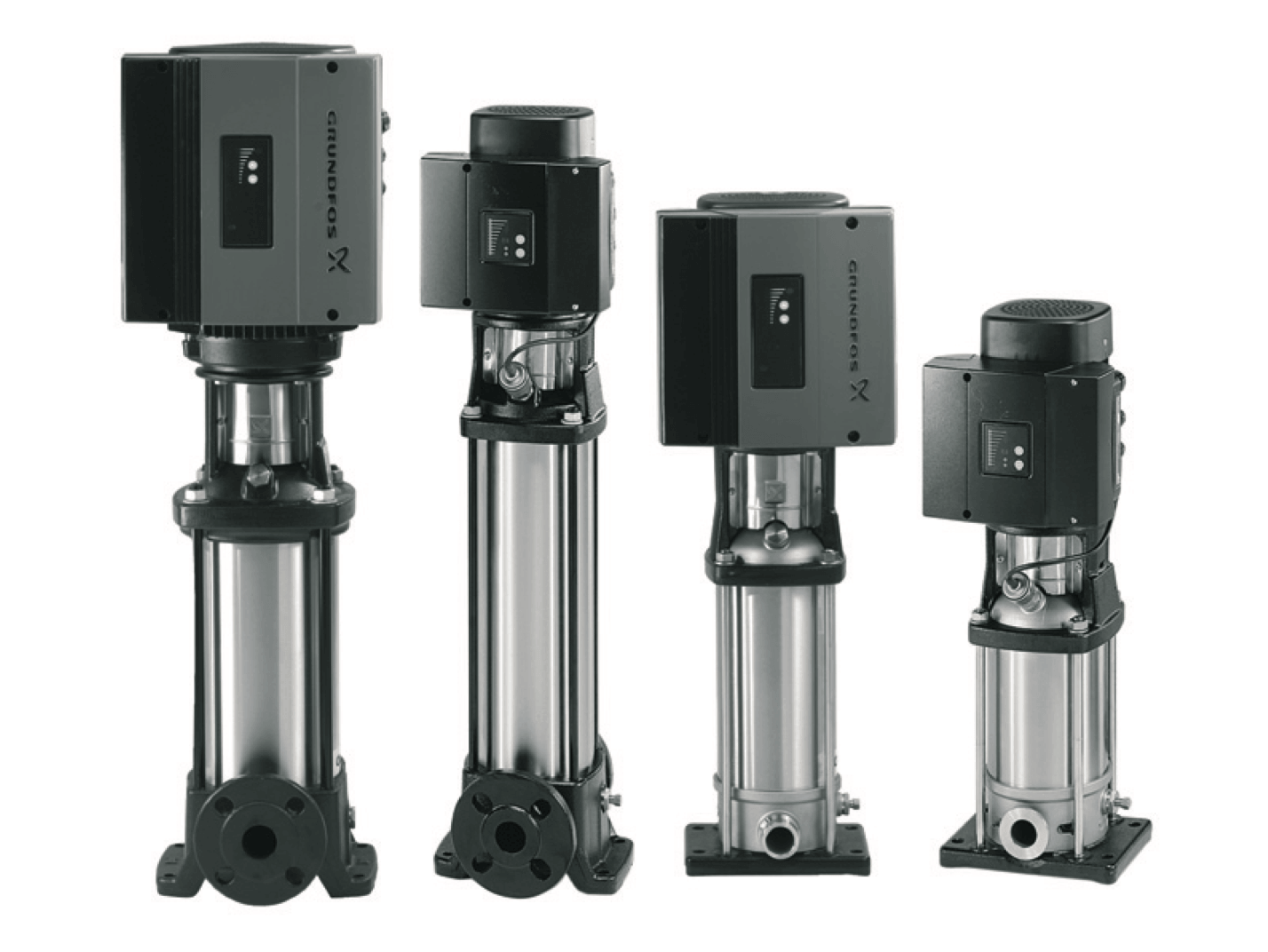

Multistage Fluid Pumps

Multistage end suction – centrifugal booster pumps. Vertical, multistage centrifugal pump with suction and discharge ports on the same level. Contact Blackhawk for detailed specs, pricing and options.

Submersible Well Water Pumps

Hydraulic design with energy efficient motors. Grundfos SP pumps are submersible borehole pumps, designed for pumping groundwater. Grundfos SP are all stainless-steel pumps, and they are available in 3 material grades. The pumps are suitable for boreholes in sizes ranging from 4" over 6" and 8" to 10". Multiple options and installation configurations are likely. Other options for submersible pumps are available. Contact Blackhawk for specs and pricing.

Wastewater Pumps

Enclosed centrifugal pump and motor with vertical or horizontal dry installation. The Grundfos S pumps are a range of free-flow channel impeller pumps specifically designed for pumping sewage and wastewater in a wide range of municipal and industrial applications.

Dosing & Disinfection Pumps

Standard system pre-engineered, assembled and tested modular unit for large or small volumes based on different technologies for flocculation, disinfection, and pH adjustment. The Grundfos Mechanical pump range is a series of extremely strong pumps for applications requiring reliable dosing and high-pressure capabilities. Mechanical pumps require minimum maintenance and are the best choice for many dosing applications. A complete line of electronic and electrochemical accessories are also available.

Industrial Process Pumps

ANSI & Vertical fluid pumps for corrosive, toxic, or abrasive process liquids. Vertical, multistage centrifugal pumps from Grundfos with integrated frequency converter. Materials in contact with the liquid are in Titanium has an exceptional resistance to a wide range of acids, alkalis, seawater and industrial chemicals.

Immersible Fluid Pumps

Vertical, multistage centrifugal and screw pumps, for mounting in tanks.

Split Case Pumps

Grundfos LS horizontal split case pump and LSV vertical split case pump are single stage or two stages, non-self-priming, centrifugal volute pumps with radial suction and radial discharge ports. End suction, immersible, similar split case and vertical turbine pumps also available.

Pump Controls & Monitoring

Mobile pump control and multi-pump controllers. Communication Interface Module/Communication Interface module is the range of communication options from Grundfos pups. Enables you to connect your product to the wide range of field bus standards. Many options and devices exist here to control your pumps and relay data in real time. Contact Blackhawk Equipment for details and options.

We Understand The Engineering Process for Fluid Pumps

Blackhawk Equipment's vast experience and detailed knowledge of engineering processes makes us the perfect partner to help you choose the right solution. Blackhawk understands your exact situation and business processes are likely propritary and unique, as industrial fluid pumps can be used across many applications, often in stages, like:

- Boiling, thermal control, and cooling

- Cleaning and washing

- Food and beverage creation

- Treatment of wastewater

- Boosting pressure for various chemical applications

Grundfos offers perhaps the broadest pump lines for a near effortless operation of industrial applications. These pumps will meet your exact requirements and are versatile enough to handle all kinds of fluid pumping applications in the field. Each of the pumps are designed and constructed to meet your industry specific requirements. Some of the typical challenges likely include:

- Chemical processing and regulations

- Movement of water without contamination

- Pressurizing fluids or water safely

- Management of large-volume fluids for positive yields

As you can see, we provide a wide selection of fluid pumps for various industrial applications at Blackhawk Equipment. We are a customer-centric company and aim to keep customer satisfaction at the top of our priority list. Contact us today and let our experienced technical sales team help you decide what pump solution will be perfect for your business.

Selecting The Right Fluid Pump

Choosing the right pump for industrial or commercial applications is a crucial task. It directly impacts the performance of the system.

Each pump comes with different specifications, and each application requires many considerations to keep in mind. With a variety of different types and styles available, it might seem like a daunting task, but always ensure you keep these four considerations in mind while searching for the right pump:

The Construction Material of The Pump

Select your pump based on the pump's construction material's ability to withstand the chemical composition of your industry's fluids. Certain pumps come with specific regulatory standards, and that should always be addressed. Some common types of materials include bronze, stainless steel, and cast iron.

Properties of the Fluids

Remember to meticulously note the properties of the fluids while selecting the right pump. Some fluid properties put extra stress and bring the pump's efficiency down. For instance, processing liquids with solids, corrosive fluids, and heated fluids require different material treatments and internal pump components.

Availability and Power Demands

Nowadays, many pumps come in electrical and gas-powered varieties for mobile applications such as agriculture and construction sites. Not all fluid pumps are made to support portable usage, so always ensure you buy the right pump to suit the power demands. Along with considering the power source, select the pump based on its voltage as well as current constraints. Pumps with high horsepower tightly control the fluid pressure and thus need reliable and continuous access to a power source.

Fluid Pressure Levels

Different fluid pumps come with different mechanisms; one component that keeps changing is the fluid pressure. Friction, kinetic energy build-up, and elevation change the fluid's pressure levels. Therefore, while selecting a pump, pay attention to the pressurizing mechanisms, submersion of the pump, and the anticipated elevation.

Contact Blackhawk Equipment for a wide assortment of specialized pumps that can cater to your varied industrial and commercial demands. If you are still trying to decide which type would suit your needs the best, approach our experienced technical sales team, and we will help you decide on the right fluid pump for your business.