Vacuum Pumps

Vacuum pumps are crucial components used in many manufacturing applications today. Their usefulness can be grasped by considering even a partial list of the industries which make use of them today: electron microscopy, photolithography, printing presses, cabinetry fabrication, glass and stone cutting, composite moulding, medical drug manufacturing, food processing and mass spectrometry. This tremendous versatility is due to the fact that vacuum pumps have the capability of removing gas from a sealed volume, so as to create a partial vacuum, after which fluids can rush in to populate the vacuum.

Blackhawk Equipment specializes in offering rotary screw vacuum pumps and vacuum air compressors, which are among the most popular types of vacuum equipment used by many of the industries mentioned above and more. Rotary vacuum pumps are those which are oil-sealed and operate on the principle of rotary displacement. When its rotor turns, gas will flow into a suction chamber until it becomes sealed by a vane. Once the interior gas becomes sufficiently compressed, an outlet valve will open. When that valve opens, a small amount of oil enters to lubricate the suction chamber, and to seal the vanes against the housing.

As opposed to a rotary vacuum pump, which primarily operates on incompressible liquids, a vacuum air compressor primarily works with gases. The typical operation of a vacuum air compressor has it taking in air from some open environment, and pressurizing that air so it can be used either for mechanical or chemical operations. This type of machine is governed by the ratio of output to input pressure, and by the size of the chamber which is used to pressurize the air. The smaller the chamber, the greater the air pressure which will be generated by the compressor.

Blackhawk Equipment is proud to carry vacuum pumps, rotary screw vacuum pumps, vacuum air compressor systems and other related equipment from leading manufacturers including Atlas Copco, Sullair and Travaini Pumps.

GHS

The GHS series – part of the Atlas Copco Oil sealed rotary screw vacuum pumps – is a range of intelligent, oil-sealed rotary screw vacuum pumps with Variable Speed Drive (VSD) technology.

- Energy efficient

- Plug-and-play

- Compact design

DZS

The Atlas Copco DZS series is innovative and equipped with Variable Speed Drive and other advanced features. This pump is built to sustainably optimize your processes for years to come.

- Variable speed drive technology

- Remote connectivity

- Highly reliable

- Flexible, modular design

- Energy-saving

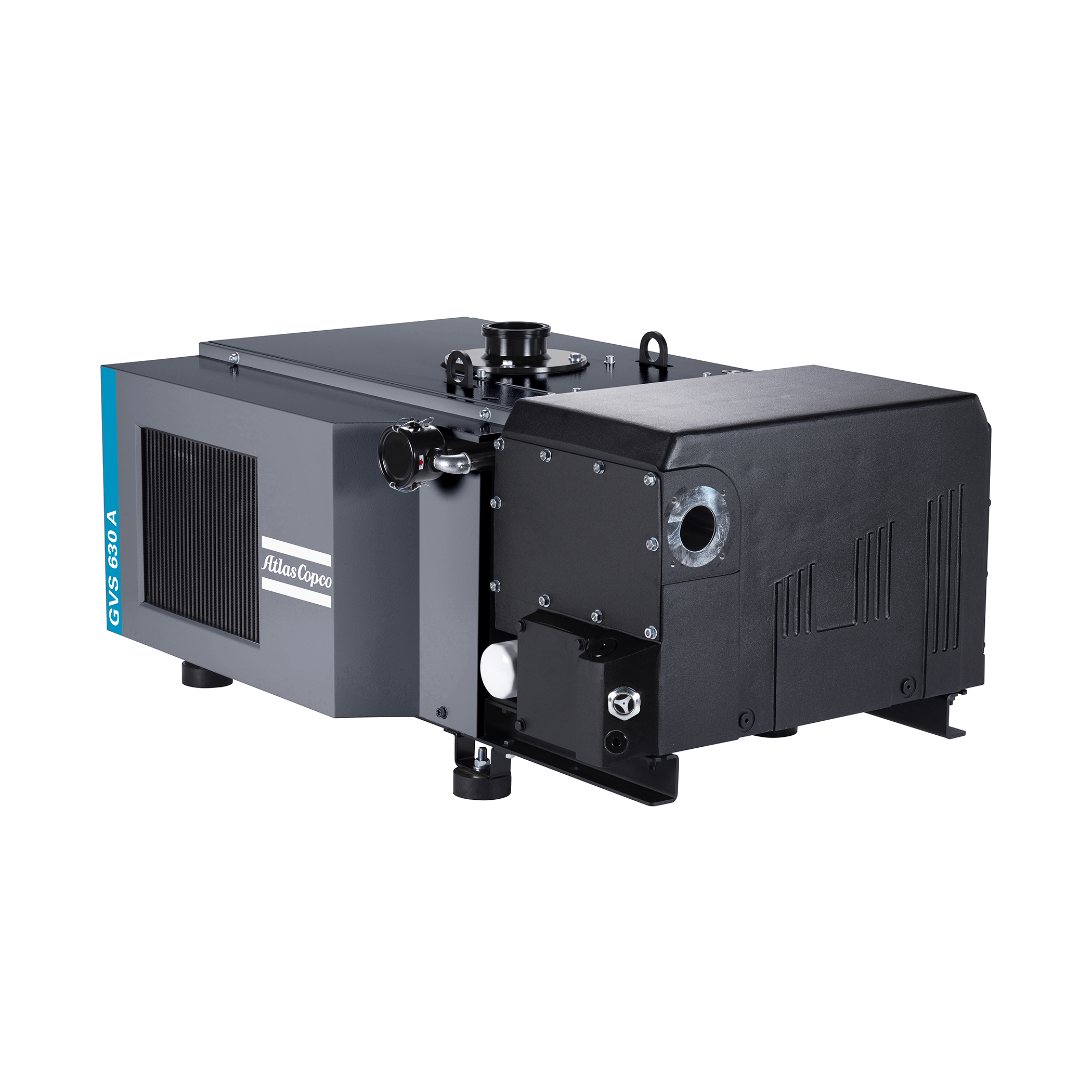

GVS

GVS – one of the Oil-sealed rotary vane pumps from Atlas Copco – is ideal for all your vacuum needs.

- Efficient and clean

- Built-in gas ballast valve

- Lubricant retention and return

- 10+ models offering pumping speeds between 16 and 840 m3/h (at 60 Hz)

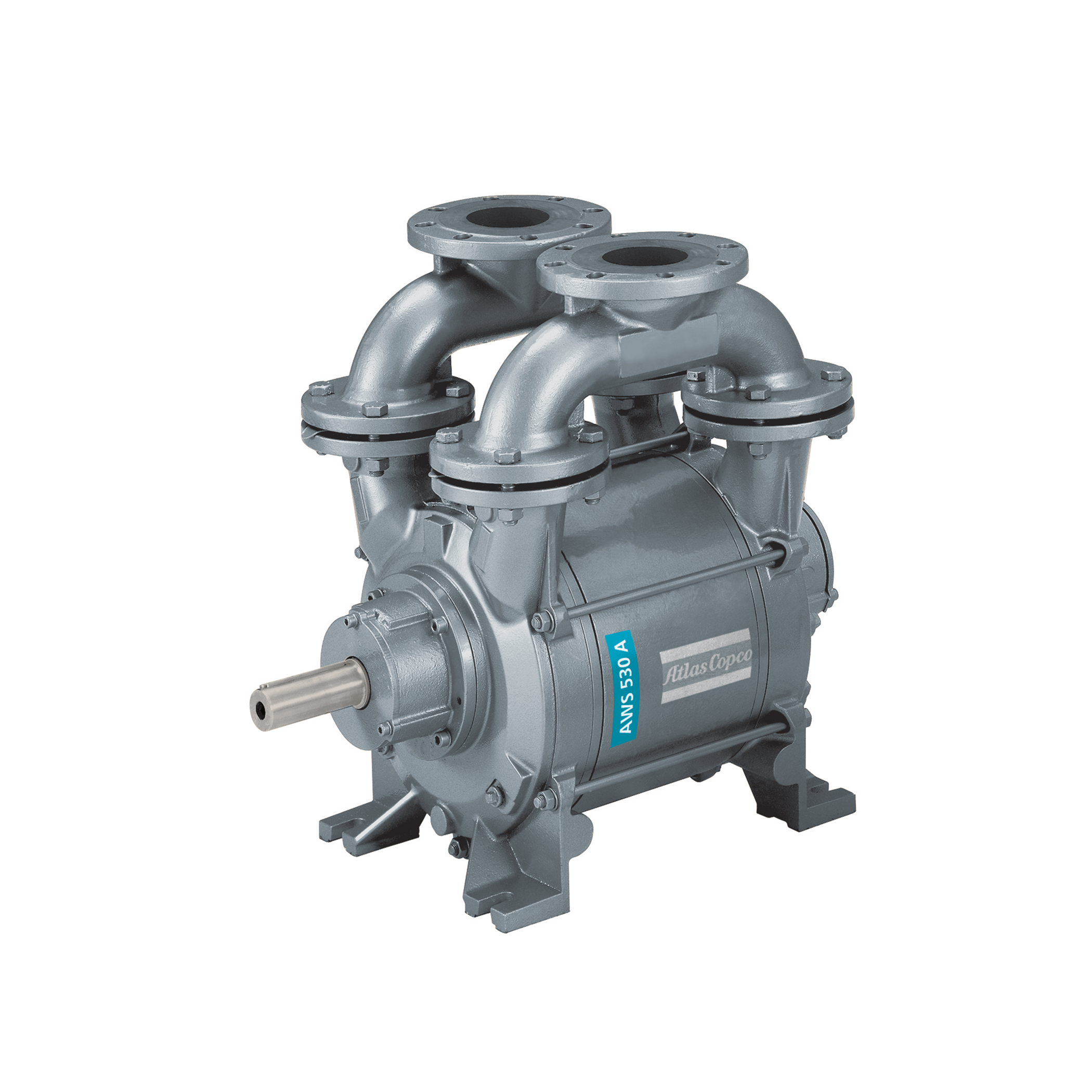

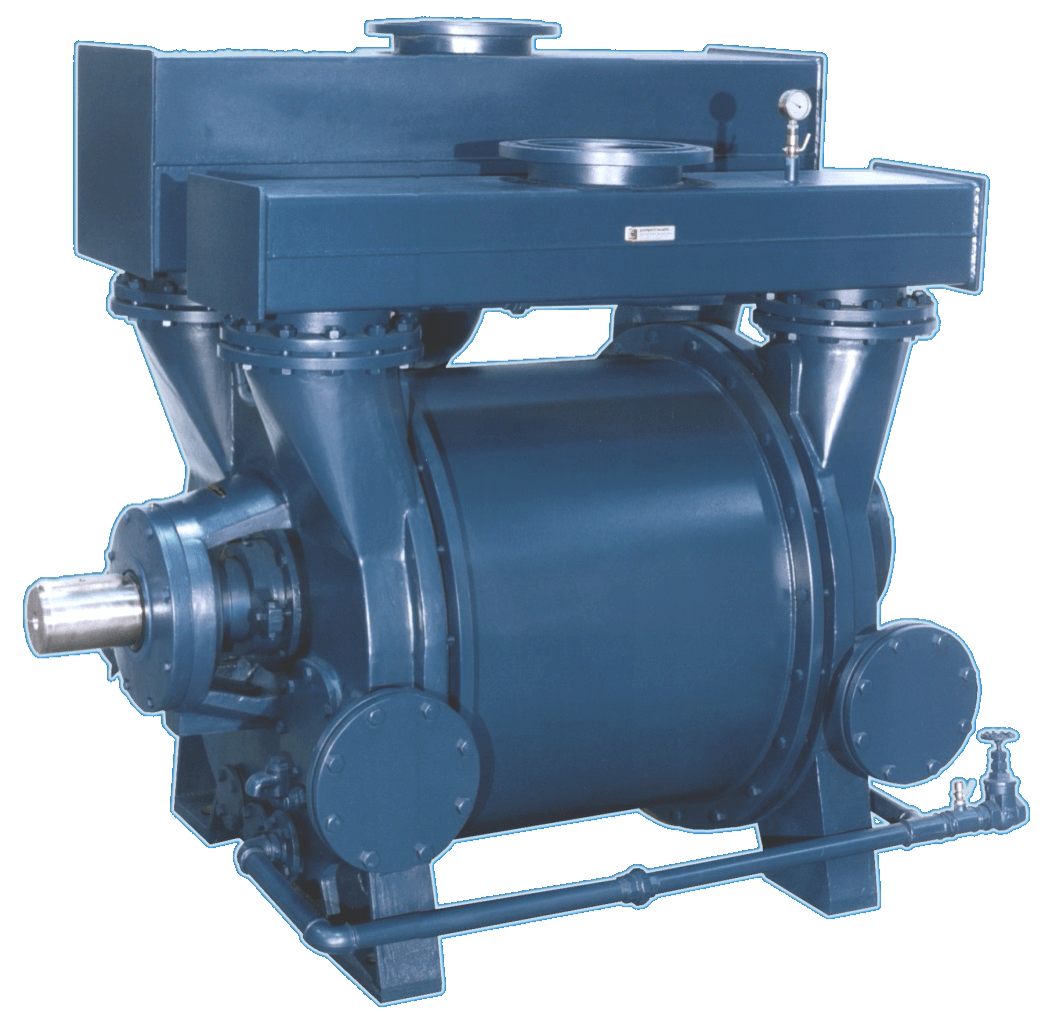

Large Liquid Ring Pump

The Atlas Copco standard liquid ring vacuum packages are perfect for use in humid, dusty and dirty environments commonly found in industrial processes. Liquid ring pumps are equipped with a fixed blade impeller located eccentrically within a cylindrical casing.

- Adaptable, tailor-made solutions

- Water recovery modules

- Suitable for harsh industrial environments

- Water-saving technology

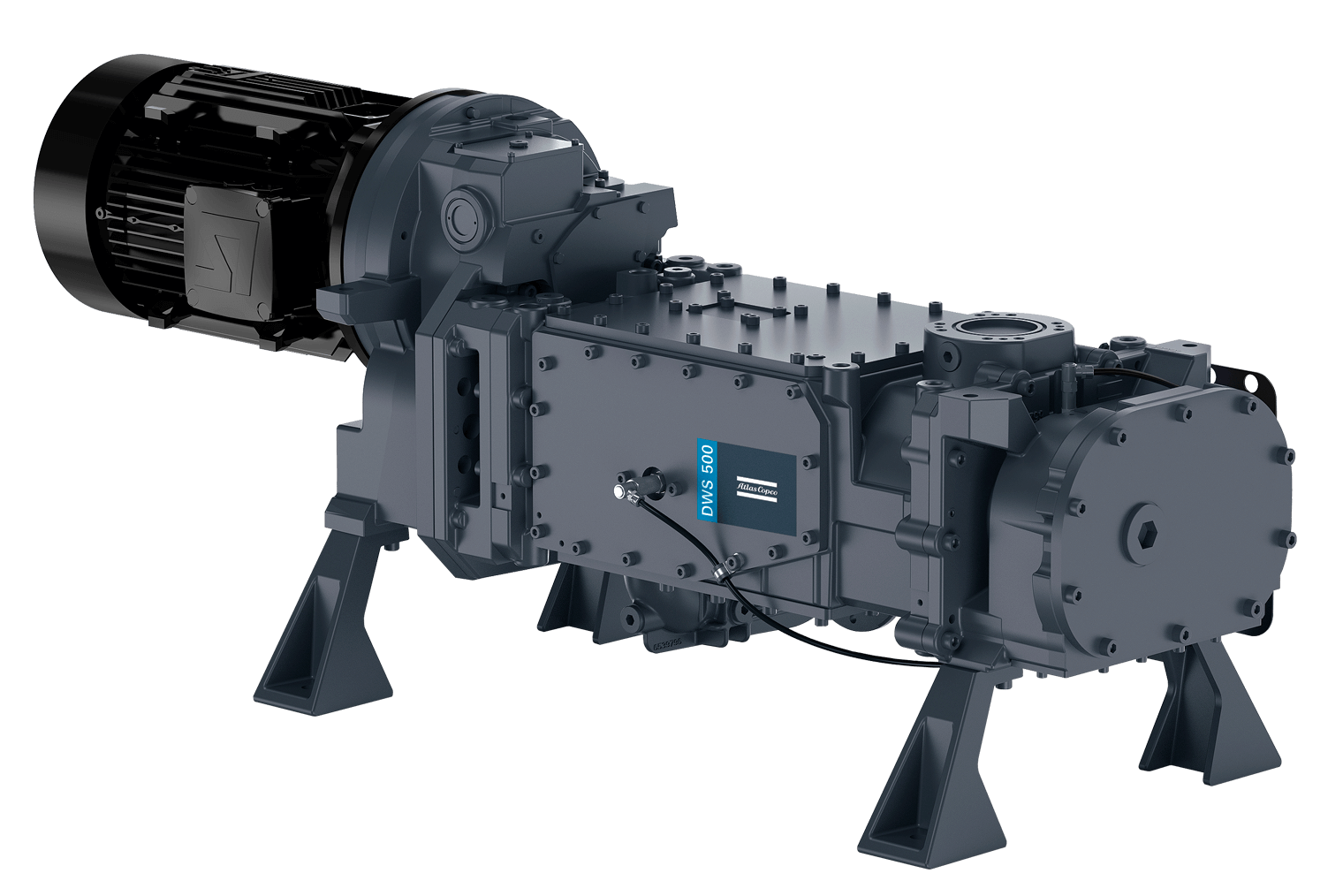

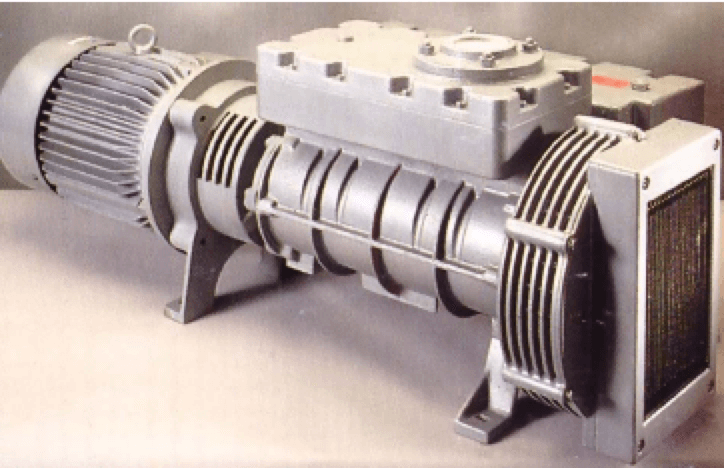

Dry Screw Vacuum Pump

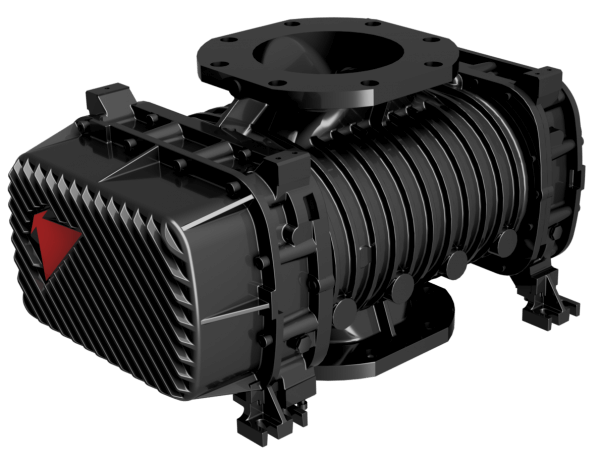

The Atlas Copco dry screw vacuum pump is a plug and play industrial vacuum pump intelligently engineered for long-life operations and designed for harsh applications.

- Increased productivity

- Minimized energy consumption

- Operator-friendly control

- Easy maintenance

- Lower operation costs

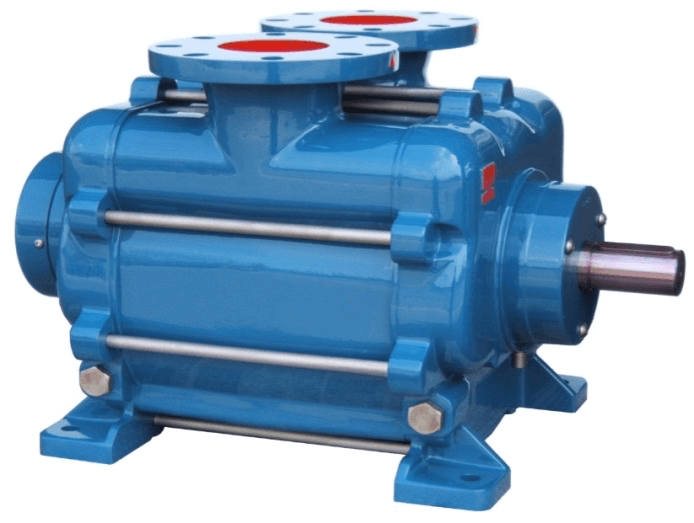

Large Capacity Pumps - TRSK / TRVK Series

Large Capacity Pumps - TRSK / TRVK Series

- Single Stage / Vari-Port

- Max Vacuum: 26”HgV 1 Stage 28.9” HgV Vari-Port

- Max Capacity: up to 17,000 ACFM

- Up to 800 HP/Belt Driven

Material of Construction:

- Casing: Cast Iron, 316 Stainless Steel

- Impeller: Ductile iron, 304/316 Stainless Steel

- Shaft: Stainless Steel

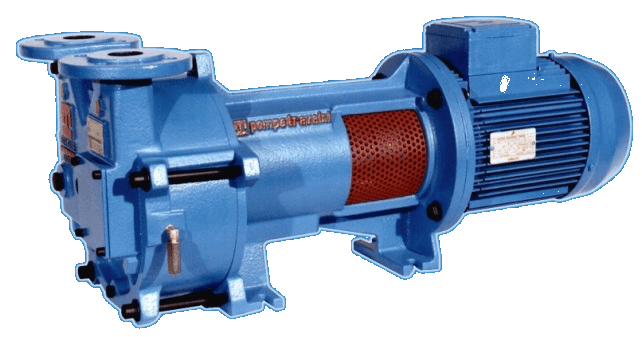

Vari-Port Vacuum Pumps - TRVA / X Lantern Mounted Motor

Single Stage TRVA / X Lantern Mounted Motor

- Max Vacuum: 28.9”HgV

- Max Capacity: 1150 ACFM

- Up to 100 HP

Material of Construction:

- Casing: Cast iron, 316 stainless steel

- Impeller: Ductile iron, 304 & 316 stainless steel

- Shaft: 420/316 Stainless steel

Vari-Port Vacuum Pump - TRVB / TRMB / TRMX

Single Stage TRVB / TRMB / TRMX

- Max Capacity: 305 ACFM

- Max Vac 28.95”HgV (25Torr)

- TRM series equipped with close coupled motor

Material of Construction:

- Casing: Cast iron, 316 stainless steel

- Impeller: Ductile iron, 304 & 316 stainless steel

- Shaft: 420/316 Stainless steel

Rotary Vane Vacuum Pump - PVL Series

- Single stage, air-cooled, oil lubricated

- Capacity: 5 to 700 CFM

- Vacuum: Up to 29.9”HgV (0.5 Torr)

- Up to 40 Hp

- Material of Construction:

- Casing: CI

- Rotor: Turned Steel

- Vanes: Carbon Epoxy Composite

Blowers and Boosters

Travaini Pumps: Boosters

|

Vacuum rate |

Range mBar

|

Max pressure bar G |

Max flow CFM |

Stages nr. |

Shaft Support |

|

Low- |

0.5 |

0 |

11000 |

1 |

Bilateral Cantilever |

Travaini Pumps: Blowers

|

Vacuum rate |

Range mBar

|

Max pressure bar G |

Max flow CFM |

Stages nr. |

Shaft Support |

|

Low- |

0.5 |

0 |

13000 |

1 |

Bilateral Cantilever |