Oil Free and Centrifugal Air Compressors

Oilless air compressors provide 100% oil free air, meeting the ISO 8573-1 Class Zero certification for applications in which air purity is essential. Additionally, operating costs are reduced with less maintenance and energy loss due to pressure drops across filtration. Blackhawk Equipment is an industry expert in recommending and installing all types of oil free air compressors for a wide variety of industries. Blackhawk Equipment offers Sullair, Ingersoll Rand, Cameron and Kobelco centrifugal compressors.

Sullair DS Series Oil-Free Air Compressors

Sullair DS Series Oil-Free Air Compressors

The Sullair DS Series delivers 100% oil-free, high-purity air, meeting ISO 8573-1 Class 0 standards for critical applications like pharmaceuticals, food and beverage, and electronics. Engineered with a robust Hitachi Two-Stage Air End, these compressors are built for long-term reliability and durability.

Key Features:

-

Oil-Free Certification: Guaranteed Class 0 oil-free air for total peace of mind.

-

Durable Design: Features a two-stage air end with stainless steel rotors for superior longevity.

- Advanced Controls: The Sullair Touch Screen (STS) Controller offers intuitive, menu-driven controls and optional remote monitoring with AirLinx® to prevent unplanned downtime.

-

Simplified Maintenance: Designed with easy-to-remove hinged panels for quick and convenient service access.

Technical Specifications:

-

Power: 60-100 hp (45−75 kW)

-

Pressure: 100-150 psi (7−10.3 bar)

-

Flow: 222−483 cfm (6.3−13.7m3/min)

-

Warranty: 3-year package warranty and a 5-year air end warranty with continuous use of Genuine Sullair parts.

Sullair DSP Series Oil-Free Air Compressors

Sullair DSP Series Oil-Free Air Compressors

The Sullair DSP Series offers advanced oil-free compression and rotary screw dependability, providing a reliable and efficient air supply for your facility. These compressors are certified to meet ISO 8573-1 Class 0 standards, ensuring the highest level of air purity for critical applications such as pharmaceuticals, food and beverage, and electronics manufacturing. The DSP Series is engineered to operate reliably and quietly, delivering cost-effective performance for the long term.

Key Features:

-

100% Oil-Free Air: Certified Class 0 oil-free air prevents contamination, which is crucial for sensitive production processes.

-

Durable and Efficient Design: Powered by a robust Hitachi two-stage air end with stainless steel rotors and a patented PTFE-free coating, engineered for high efficiency and long life.

-

Quiet Operation: Features a noise-reducing package that includes a full enclosure and vibration isolation, allowing for installation in various environments.

-

Easy Maintenance: Designed with maintenance-friendly features like easy access to filters and external grease fittings on larger motors, simplifying service.

-

Advanced Control System: Includes a simple LCD monitor screen with Lead/Lag capability and optional communication protocols like MODBUS and BACnet.

Technical Specifications:

-

Power: 30-300 hp (22−240 kW).

-

Pressure: Up to 145 psi (10 bar).

-

Flow: 114−1430 cfm (3.2−40.5m3/min).

-

Sound Levels: As low as 65 dBA.

-

Warranty: 3-year package warranty and a 5-year air end warranty when serviced with Genuine DSP parts.

Sullair SRL Series Oil-Free Scroll Air Compressors

Sullair SRL Series Oil-Free Scroll Air Compressors

The Sullair SRL Series uses advanced scroll technology to deliver clean, 100% oil-free air, meeting ISO 8573-1 Class 0 standards for the most demanding applications. These compressors are perfect for industries where air purity is essential, such as pharmaceuticals, food and beverage, and dental applications. The compact and exceptionally quiet design allows for point-of-use installation, reducing piping and installation costs.

Key Features:

-

Certified Oil-Free: Provides certified Class 0 oil-free air, eliminating the risk of contamination in critical processes.

-

Ultra-Quiet Operation: With noise levels as low as 48 dBA, these compressors are significantly quieter than typical factory machinery, making them ideal for indoor environments without a separate sound room.

-

Energy-Efficient Controls: Features patented Multi-Drive Control (on multiplex units) and Cycle Control Logic to optimize performance, save energy, and extend the life of the compressor.

-

Compact and Flexible Design: The small footprint and low noise level allow for flexible installation right at the point of use, saving valuable floor space.

-

Durable Scroll Technology: A patented scroll wrap and proprietary tip seal design provide superior performance and extend service intervals, ensuring long-term reliability.

Technical Specifications:

-

Power: 2-44 hp (1.5−33 kW).

-

Pressure: Up to 145 psi (10 bar).

-

Warranty: A 3-year package warranty and a 5-year air end warranty when continuously serviced with Genuine Sullair parts.

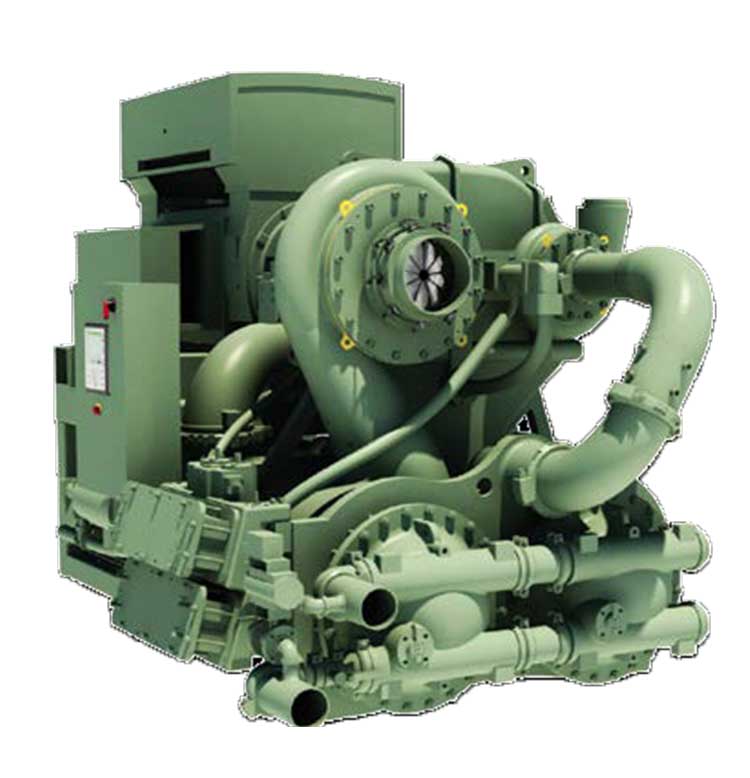

Centrifugal f-Series

Sullair f-Series Centrifugal Compressors

The Sullair f-Series centrifugal compressors are high-performance, custom-designed machines built to meet your specific needs. Offering a high degree of flexibility, the f-Series provides a broader range of pressure and flow options with available single-stage up to four-stage compression. This series features the same core benefits as the T-Series, including a robust design and easy maintenance features.

Key Features:

-

Highly Flexible Design: Available in both packaged and non-packaged options. Can be custom-configured for a wide range of pressures and flows.

-

High-Pressure Capabilities: Certain models can achieve pressures from 230 to 725 psi, making them suitable for recycle and booster air compressor applications.

-

Energy-Efficient: Designed for high efficiency to reduce energy usage.

-

Simplified Maintenance: A horizontally-split gearbox design allows for easy access to all moving parts, simplifying maintenance and reducing downtime.

Technical Specifications (Varies by model):

-

Flow: 1200-118,000 cfm.

-

Pressure: 15-725 psi.

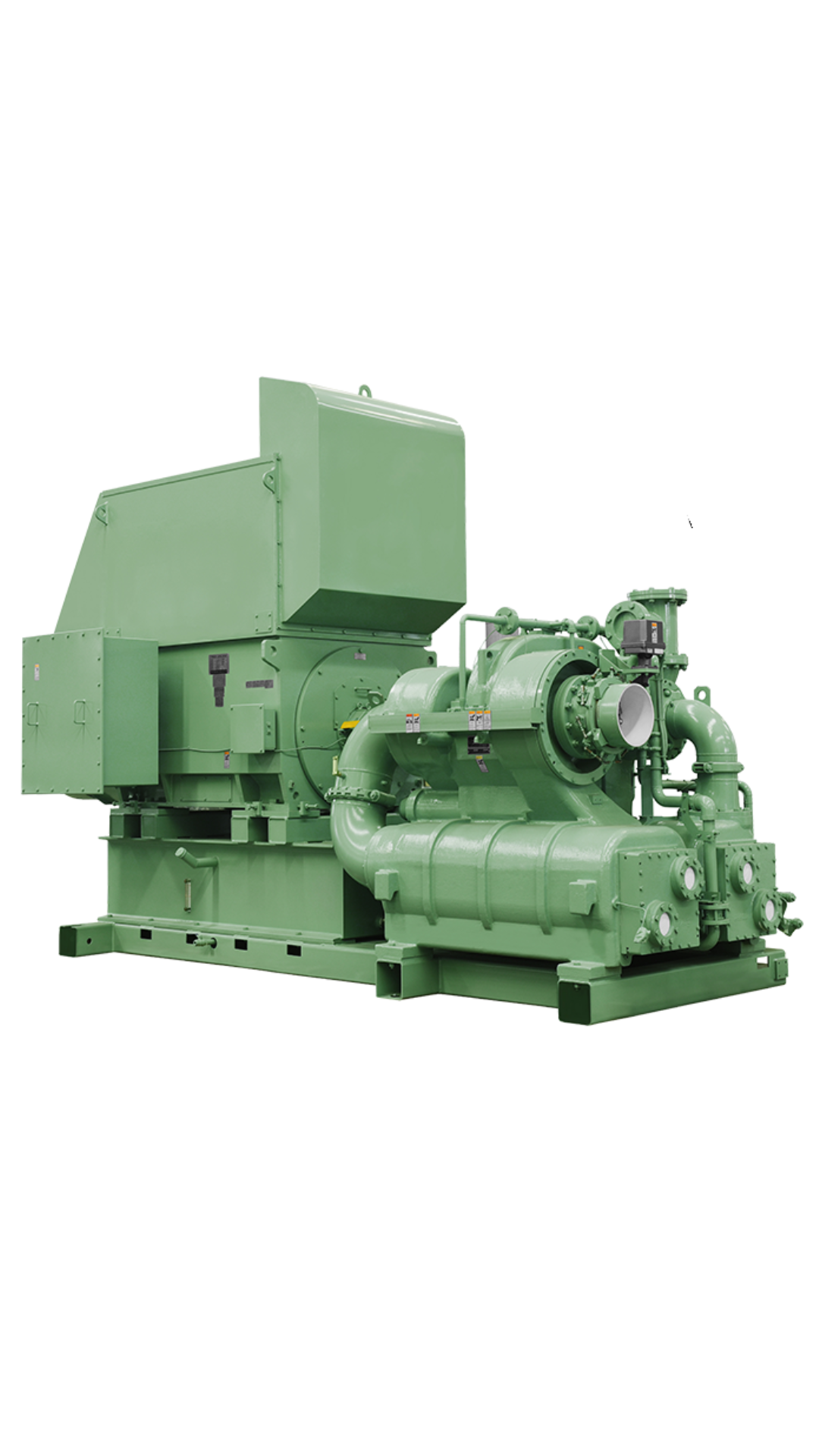

Centrifugal T-Series

Sullair T-Series Centrifugal Compressors

The Sullair T-Series centrifugal compressors are engineered for unparalleled reliability and durability. These models come in a complete package, with a robust, time-proven design ideal for heavy-duty applications like oil and gas, manufacturing, and chemicals. Featuring a horizontally-split gearbox and non-contacting internal components, the T-Series offers low maintenance and easy accessibility for inspection.

Key Features:

-

Certified Oil-Free: Delivers 100% oil-free air, meeting ISO 8573-1 Class 0 standards for critical applications.

-

Energy-Efficient Design: Advanced impellers and Inlet Guide Vanes (IGV) optimize aerodynamics to reduce power consumption by up to 10% during partial load operation.

-

Reliable Components: Includes titanium impellers as a standard for added strength and resistance to corrosion and wear. TRX models feature stainless steel impellers.

-

Advanced Controls: An advanced PLC control system allows for easy tracking of system performance, with standard Allen-Bradley or Siemens controls.

Technical Specifications (Varies by model):

-

Power: 275-2300 hp (210−1715 kW).

-

Pressure: 30-230 psi.

-

Flow: 1050-11750 cfm.

High Pressure Up To 610 PSI, MSG & API Options Available!

Blackhawk Equipment Offers Factory-Trained Service and OEM Parts for:

Centrifugal - MSG Turbo Air

- 505 – 14,750 cfm (15.5 – 417 m³/min),

- 50-150 psi (3.8 – 10.3 bar)

- 125-3700 HP (93 -2670 kW)

Centrifugal MSG Turbo Air Cooled 2000

- 550 to 1700 CFM (16 to 48 m3/min)

- 125 to 350 hp (93 to 260 kW)

- 50 to 150 psi, (3.5 to 10.3 bar)

Centrifugal MSG Turbo Air NX Series

- 4850 – 15,200 cfm (135 – 430 m³/min)

- 35-210 psi (2.5 – 14.5 bar)

- 1000-3000 HP (750 -2237 kW)

Centrifugal Heat of Compression Dryer Package - Turbo DryPak

- 550 – 4000 cfm (15.6 - 113 m³/min)

- 150-800 hp (112-597 kW)

- 55 to 150 psig (3.8 – 10.3 barg)

Oil Free Rotary Screw – KNW Series

Two stage, air and water cooled, fixed and variable speed

- 20-500 HP Fixed Speed

- 25-550 HP Variable Speed

- 40-150 PSIG

- 20-500 HP, 72-2400 ACFM

Air Cooled machines available up to 350 HP

Water Cooled from 20-550 HP