Air Treatment Dryers & Filtration

Sullair Desiccant Compressed Air Dryers

Sullair Desiccant Compressed Air Dryers are engineered for the most critical applications, providing clean, dry air where you need it most. They are ideal for applications that require an extremely low dewpoint of

−40∘F/−40∘C. The dual-tower design uses desiccant material to adsorb moisture from saturated compressed air, ensuring downstream equipment is protected from contamination.

Sullair Desiccant Dryer: SAV Series

Sullair Desiccant Dryer: SAV Series

The SAV Series uses a combination of an external heat source and a blower to regenerate the desiccant material, using an average of only 2% of the process air. This three-tiered method helps optimize the drying process and maximize energy cost savings.

Key Features:

- Blower regeneration technology with a heat source helps save energy.

- An Allen-Bradley® PLC Color Touch Screen Controller is included.

- The Sullair Desiccant Dryer (SDD) Energy Management System matches supply to demand for up to 80% energy savings.

- Engineered to stand up to harsh environments.

- Remote monitoring of operation status, data trends, and alarms via email or text alerts is available.

Technical Specifications:

-

Flow Rate: 500 to 7500 cfm.

-

Dewpoint Performance: −40∘F/−40∘C.

-

Average Purge Air: 2%.

Sullair Desiccant Dryer: SA Series (Externally Heated)

Sullair Desiccant Dryer: SAH Series (Externally Heated)

The SAH Series is an energy-efficient option that uses an external heat source to enhance the regeneration process. This method reduces process air loss, consuming an average of only 8% of the air during regeneration.

Key Features:

- An external heat source helps save energy.

- Includes an Allen-Bradley® PLC Color Touch Screen Controller.

- The Sullair Desiccant Dryer (SDD) Energy Management System matches supply to demand for up to 80% energy savings.

- Features a heatless backup for more uptime and dewpoint control.

- Engineered to stand up to harsh environments and includes a rugged frame with forklift pockets.

Technical Specifications:

-

Flow Rate: 500 to 3000 cfm.

-

Dewpoint Performance: −40∘F/−40∘C.

-

Average Purge Air: 8%.

Sullair Desiccant Dryer: SA Series (Heatless)

SA Series (Heatless)

The SA Series uses a portion of dried process air to regenerate the desiccant material. This is an economical and reliable option for applications that require extremely low dewpoints.

Key Features:

-

Provides −40∘F/−40∘C dewpoint performance.

- A high-performance switching valve system delivers worry-free operation.

- The standard controller is an Allen-Bradley® PLC Basic Controller.

- Optional enhanced and advanced controllers are available with features like a touch screen and the SDD Energy Management System for up to 80% energy savings.

- Engineered for harsh environments and comes with a NEMA 12 enclosure.

Technical Specifications:

-

Flow Rate: 55 to 3000 cfm.

-

Dewpoint Performance: −40∘F/−40∘C.

-

Average Purge Air: 15%.

Sullair Desiccant Modular Compressed Air Dryer: DMD Series (Modular)

Sullair Desiccant Modular Compressed Air Dryer: DMD Series (Modular)

The DMD Series is a compact and completely automatic desiccant dryer designed for point-of-use placement. Its modular design is ideal for smaller applications where space is a concern.

Key Features:

- Compact design with a mini PLC monitor.

- Inlet and purge manifold design for low pressure drop.

- Energy-efficient demand cycle control is an available option.

-

Offers dewpoint options of −4∘F (−20∘C) or −100∘F (−73∘C).

Technical Specifications:

-

Flow Rate: 3 to 240 cfm.

-

Min/Max Operating Pressure: 58/232 psi.

-

Min/Max Inlet Air Temp: 50∘F/122∘F.

Additionally, Blackhawk Equipment offers refrigerated dryer factory-trained service and aftermarket solutions from these manufacturers:

![]()

Sullair Refrigerated Compressed Air Dryers

Sullair Refrigerated Compressed Air Dryers reliably remove harmful moisture and contaminants from compressed air, protecting your equipment and downstream tools from damage. They operate by chilling the air to a set dewpoint, which causes condensate to separate and be discharged from the system.

Sullair Refrigerated Compressed Air Dryers SRN Series

Sullair Refrigerated Compressed Air Dryers SRN Series

The SRN Series is ideal for applications running at full capacity. These dryers maintain constant energy consumption and a stable dewpoint in varying operating conditions through a hot gas bypass system. The dryers utilize a low-GWP (Global Warming Potential) refrigerant, R513A.

Key Features:

- An all-in-one aluminum heat exchanger provides energy efficiency and low pressure drop.

- The refrigeration circuit is designed to minimize the volume of refrigerant used.

- Models 1400 cfm and up feature electronic hot gas bypass and variable speed fans for increased energy efficiency and reduced refrigerant usage.

- Models 2000 cfm and up have inlet/outlet connections on both sides for easy installation.

- A 2-year bumper-to-bumper warranty is included.

Technical Specifications:

-

Flow Rate: 10 to 6000 cfm.

-

Max Inlet Pressure: 232 psi (for models 10-175 cfm) and 203 psi (for models 200-6000 cfm).

-

Outlet Pressure Dew Point: 37−45∘F.

Sullair Refrigerated Compressed Air Dryers SRD Series

Sullair Refrigerated Compressed Air Dryers SRD Series

The SRD Series is ideal for operations with variable flow rates and fluctuating air demand. Its energy-saving cycling technology allows the refrigeration circuit to run intermittently, matching supply to demand and increasing energy efficiency while maintaining a stable dewpoint. These dryers also use the low-GWP refrigerant R513A.

Key Features:

- Energy-saving cycling technology matches supply to demand at partial loads.

- The all-in-one aluminum heat exchanger provides energy efficiency and a low pressure drop.

- A scroll compressor is included on models 325 cfm and up for lower noise, longer life, and increased energy efficiency.

- Digital LED controllers with remote connectivity are standard, and models 700 cfm and up offer a touch screen controller for easy access to performance data.

- A 2-year bumper-to-bumper warranty is included.

Technical Specifications:

-

Flow Rate: 75 to 6000 cfm.

-

Max Inlet Pressure: 232 psi (for models 200-6000 cfm) and 203 psi (for models 75-175 cfm).

-

Outlet Pressure Dew Point: 37−45∘F

Additionally, Blackhawk Equipment offers desiccant dryer factory-trained service and aftermarket solutions from these manufacturers:

- iSTE, iSTUE - Single Tower Blower Purge Desiccant. Flow rates from 60-3000 scfm.

- iDHE – Heatless Regenerative Desiccant. Flow rates from 15-1500 scfm.

- iDOFE – Heatless Oil Field. Flow rates from 15-800 scfm.

- iDHPE – Heat Reactivated. Flow rates from 100-8000 scfm.

- iDBPE – Blower Purge. Flow rates from 130-6000 scfm.

- HHL Series, HHS Series & HHE Series - Heatless Regenerative Desiccant Dryers. Flow rates from 40 – 5,400 scfm

- HPD Series - Heated Blower Purge Desiccant Dryers. Flow rates from 300-3200 scfm.

- HBP Series - Blower Purge Regenerative Desiccant Dryers. Flow rates from 500-4300 scfm.

- DHW Series - Heatless Regenerative Desiccant Dryers. Wall mount 7-50 scfm.

- HDF Series - Single Tower Desiccant Dryers. Point of use 5-30 scfm.

- HCD Series - Heat of Compression Desiccant Dryers. Flows of 350-1000 scfm.

Additionally, Blackhawk Equipment offers desiccant dryer factory-trained service and aftermarket solutions from these manufacturers:

![]()

Membrane Dryers

Cost effective, point of use dryers from:

![]()

and

SPX Hankison Breathing Air Dryers

CBA series handles removes contaminants to meet OSHA, CGA, ANSI, and CSA breathing air standards.

- Flow rates from 15 – 940 scfm

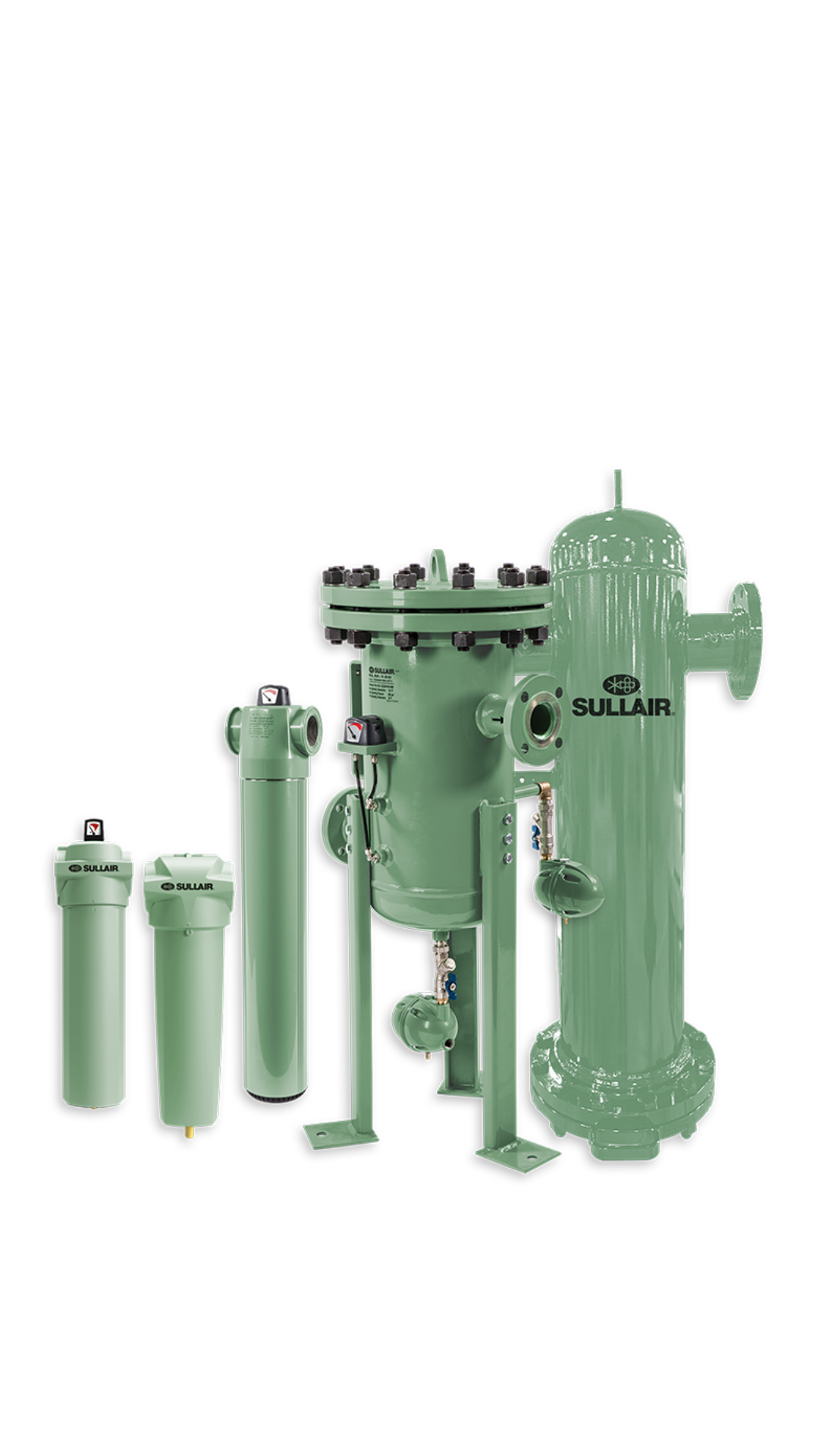

Filtration & Mist Eliminators

Sullair's filtration and mist elimination systems are designed to provide clean, dry compressed air, protecting both downstream equipment and production processes. The filter offerings are tailored for different application needs, from general-purpose protection to the removal of oil vapor for critical processes.

OptimalAir® Inlet Filter

The Sullair OptimalAir® inlet filter is engineered to be the industry's most efficient, capturing contaminants before they can reach the compressor. Its heavy-duty, high-capacity design protects internal components, extends compressor life, and reduces pressure drop to save on energy costs.

Key Features:

-

Superior Filtration: Provides 99.9% efficiency per ISO 5011, with a filtration capacity down to 0.4 micron.

-

Extended Lifespan: Its heavy-duty design holds up to five times more contaminant than conventional cellulose filters, which extends the life of internal components and compressor fluid.

-

Energy Savings: The low pressure drop throughout its operating life helps to reduce energy costs.

Compressed Air Filters

Sullair's filtration series includes various models designed to meet specific air quality needs:

-

SF Series: This series includes General Purpose (SFGP), Fine Particulate (SFFP), Activated Carbon (SFAC), and Water Separation (SFWS) filters for a wide range of applications from 21 to 11,019 cfm.

-

FH Series: High-Pressure threaded filters, with flow rates from 60 to 1750 cfm.

-

High-Temperature Filters: These filters are available as threaded (FXFRHT) and flanged (FWFRHT) models, with flow rates from 25 to 17,700 cfm respectively.

Key Features:

-

Energy Efficiency: Engineered for energy efficiency, these filters help reduce operating costs through extremely low pressure drop.

-

High-Purity Air: The SF Series is designed for applications requiring the highest purity, such as Food & Beverage and Pharmaceuticals.

-

Durable Construction: The filter housings are built for corrosion resistance and are designed for safe and easy maintenance.

-

Advanced Design: Features a pleated filter design for maximum efficiency and extended filter life.

Mist Eliminators (M Series)

Sullair Mist Eliminators are designed for the bulk removal of condensate before compressed air enters the main filtration system.

Key Features:

-

Bulk Moisture Removal: Provides a crucial pre-filtration stage by removing large amounts of water and oil mist, reducing the load on downstream filters.

-

Durable Construction: The M Series eliminators are built to last and to operate in demanding environments.

Technical Specifications (General for Filters and Mist Eliminators):

-

Flow: 5 to 11,000 cfm.

-

Pressure: Up to 230 psi.

Mist Eliminators (ELM Series)

Sullair ELM Series Mist Eliminators provide reliable performance with extremely low pressure drop, helping to save energy and protect downstream equipment. They are designed for a longer service life with a strong stainless steel support sleeve construction.

Key Features:

-

Energy Savings: The element's ultra-low differential pressure of 0.05 psi saves approximately 2% in compressor energy consumption.

-

Durable Construction: Features a strong stainless steel support sleeve to prevent rust and corrosion.

-

High-Capacity Element: The special, machine-pleated element construction provides 9-10x greater surface area and dirt-holding capacity compared to conventional media.

Technical Specifications:

-

Flow Rates: Available from 21 to 17,700 cfm, depending on the model.

-

Maximum Operating Pressure: Up to 725 psi for High-Pressure filters.

-

Filtration Micron Rating: Down to 0.003 µm for activated carbon filters and 0.01 µm for fine particulate filters.

-

Operating Temperature: Maximum operating temperature of 350∘F for high-temperature filters.

Condensate Management

Oil water separators- Air systems generate condensate that contains a combination of water, oil and other contaminants. These contaminants must be properly contained and disposed of.

Oil Water Seperators

Sullair SP Oil/Water Separators

Sullair SP Oil/Water Separators

Sullair SP oil/water separators provide an easy, convenient, and cost-effective solution to filter condensate discharge and help keep your compressor room EPA compliant. This non-cartridge option uses molecular filtration and is designed to work with all compressor fluids, including polyglycol and silicone.

Key Features:

-

Maintenance-Free Design: The system is maintenance-free, with no pumps, sensors, or pre-separation filter pads. There are no messy elements to change, as the entire unit is replaced when full.

-

No Power Required: These units require no electricity to operate, further reducing costs.

-

Reliable Performance: Performance is not affected by specific gravity, emulsification, or relative humidity. The separators can manage all types of compressor fluids, including emulsified condensate.

-

Environmentally Friendly: Spent units can be disposed of at most sanitary landfills once excess liquid is drained.

Technical Specifications:

-

Flow Rate: 20-3000 cfm.

-

Max Operating Pressure: 175 psi.

-

Max Condensate Temperature: 155∘F.

-

Oil Carryover: <10 ppm.

Additionally, Blackhawk Equipment oil water separator options from these manufacturers:

Drains

Drains- Remove condensate from compressors, dryers and filtration. They key is minimizing valuable compressed air loss. Drains often pay for themselves in less than a year.

Electric and pneumatic options to meet all sorts of applications including high and low pressure, high temperature, older systems containing rust and debris.

and

Sullimax™ Condensate Drains

Sullimax™ Condensate Drains are engineered to reliably remove condensate from your compressed air system while providing maximum energy savings. These sensor-controlled drains are a "true zero loss" solution, helping to save both time and money on maintenance.

Key Features

-

Zero-Loss Operation: Provides true zero loss for maximum energy savings.

-

High Reliability: Features an integrated sieve, eliminating the need for y-strainers and ensuring high reliability.

-

Sensor-Controlled: The drain is sensor-controlled and can automatically clear clogs and debris.

-

Easy Maintenance: Designed for low maintenance, making routine servicing fast and easy.

-

Integrated Alarm: Includes an integrated alarm with visual status indications on the drain itself. Remote access is also available.

Technical Specifications

-

Max Pressure: Up to 232 psi.

-

Flow Rate: Supports compressor flow rates up to 50,000 cfm, dryer flow rates up to 100,000 cfm, and filter flow rates up to 500,000 cfm.

-

Operating Temperature: The standard operating temperature ranges from 33∘F to 140∘F.

-

Voltage: Standard voltage is 95-240 VAC, 50/60 Hz. Optional voltages are also available.

-

Typical Application Areas: Can be used at the compressor, dryer, and filter.

Xcel Energy offers rebates on energy efficient air treatment. Send us an email to inquire today!