Air Audit Services

Save energy, reduce costs and improve system reliability with a comprehensive air system audit by Blackhawk Equipment.

Save energy, reduce costs and improve system reliability with a comprehensive air system audit by Blackhawk Equipment.

Our team has two employees who are Certified Compressed Air System Specialists (CCASS) by the Compressed Air & Gas Institute. CAGI’s personnel certification program for compressed air system specialists provides a means of verifying the capabilities of professionals in the compressed air systems industry. We also have 5 Department of Energy AirMaster+ Specialists. This means our customers get the best service and comprehensive answers to air system improvements.

Discover:

What is an Air Audit?

What are the Benefits?

Why Choose Blackhawk?

What are the Levels of Assessment in an Air Audit?

What is an Air Audit?

We understand that each plant is unique and believe there is no such thing as a “one size fits all” solution to meet everyone’s needs. We look at the system as a whole, then match the correct measure specific to the system.

What Are the Benefits of An Air Audit?

A comprehensive review of your entire compressed air system can help you:

- Decrease your system operating costs

- Discover the source of the problem rather than alleviating the symptoms

- Improve air quality

- Identify opportunities for improvements

- Provide a factual basis for evaluating opportunities, calculating savings, sizing components, verifying retrofit results and performance contracting

- Enhance productivity by reducing scheduled downtime and scrap rates

Why Choose Blackhawk Equipment as your Air System Service Provider?

Make your compressed air system more efficient and affordable with rebates and cost savings from Xcel Energy.

Energy costs for inefficient compressed air systems can account for up to 76% of lifetime equipment costs. Just a single 1/8” hole can cost you up to $2,000 in wasted energy costs each year! There are so many ways to save money, which is why Blackhawk Equipment is the best option for maximizing your savings and leading you through the process.

Benefits

- Receive funding for the study on how to improve your compressed air system

- Information on substantial rebates that offset upfront costs and shorten payback periods on new equipment

- Reduce your air waste as much as 50%

- Improve productivity and increase your profitability

- Blackhawk Equipment provides you with the most accurate data available because we measure true KW not just amps.

- All of our auditors have been properly trained and certified so that our customers can feel confident they are dealing with the most qualified individuals in the industry.

- We have 2 CCASS professionals and 5 Department of Energy AirMaster+ Specialists on staff who perform and oversee all aspects of our auditing program.

- As an Xcel Energy recipient of the 2019 Energy Efficiency Partner Awards, Blackhawk knows how to save you money with a variety of the best energy rebate programs for your specific business.

What to Expect

- Blackhawk Equipment will analyze your supply and demand usage via airflow and/or electric metering. Our comprehensive report will identify leaks, wastes and associated costs and offer recommendations and financial analysis.

- When you implement identified eligible measures from the study, you can receive Xcel Energy rebates that improve your return on investment (you are not required to participate in the Compressed Air Study in order to implement measures).

- Implement Custom Measures. Customers who participate in the Xcel Energy pre-approved custom Compressed Air Efficiency project can receive up to $600/ kW.

- Implement Prescriptive Measures. Customers who participate in our prescriptive program (no pre-approval required) can receive a rebate for equipment ranging from $200 for a No Loss Air Drain to $7,000 for a VSD compressor as examples.

What Are the Levels of Assessment in an Air Audit?

Walk-Through Air System Evaluation

Walk-Through Air System Evaluation

(1/2-2 Days)

Using the SystemWizard system analysis software we can quickly evaluate the cost and efficiency of a compressed air system, compare multiple compressor alternatives and calculate investment paybacks on energy saved. This is an ideal tool for a system walk-through assessment as defined by the Compressed Air Challenge/DOE.

System Assessment

(2-5 Days)

Our SysteMate hardware and software provide you with a real-time assessment of your company’s compressed air usage thru limited data logging. SysteMate takes power and pressure readings as inputs then calculates the true flow output, automatically generating a report which graphs system parameters, including air flow. All of this is done without any production interruptions. This assessment is typically confined to data gathering in the compressor room.

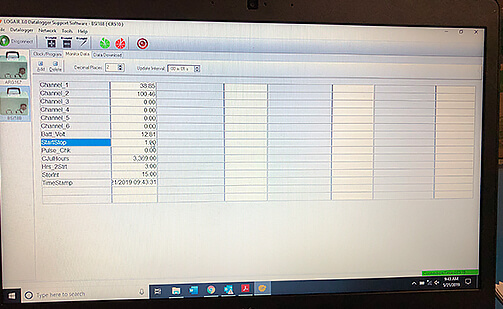

System Audit

(3-10 Days)

Our LogAir Auditing System combines the first data logging system specifically designed to meet the comprehensive requirements of today’s compressed air system. We personally train the auditors so they can provide the ultimate in compressed air system analysis and optimization. This assessment typically addresses supply and demand data logging. Our auditors work with you to understand your needs even going beyond the requirements defined by the Compressed Air Challenge and DOE.