How Has Blackhawk Helped Customers?

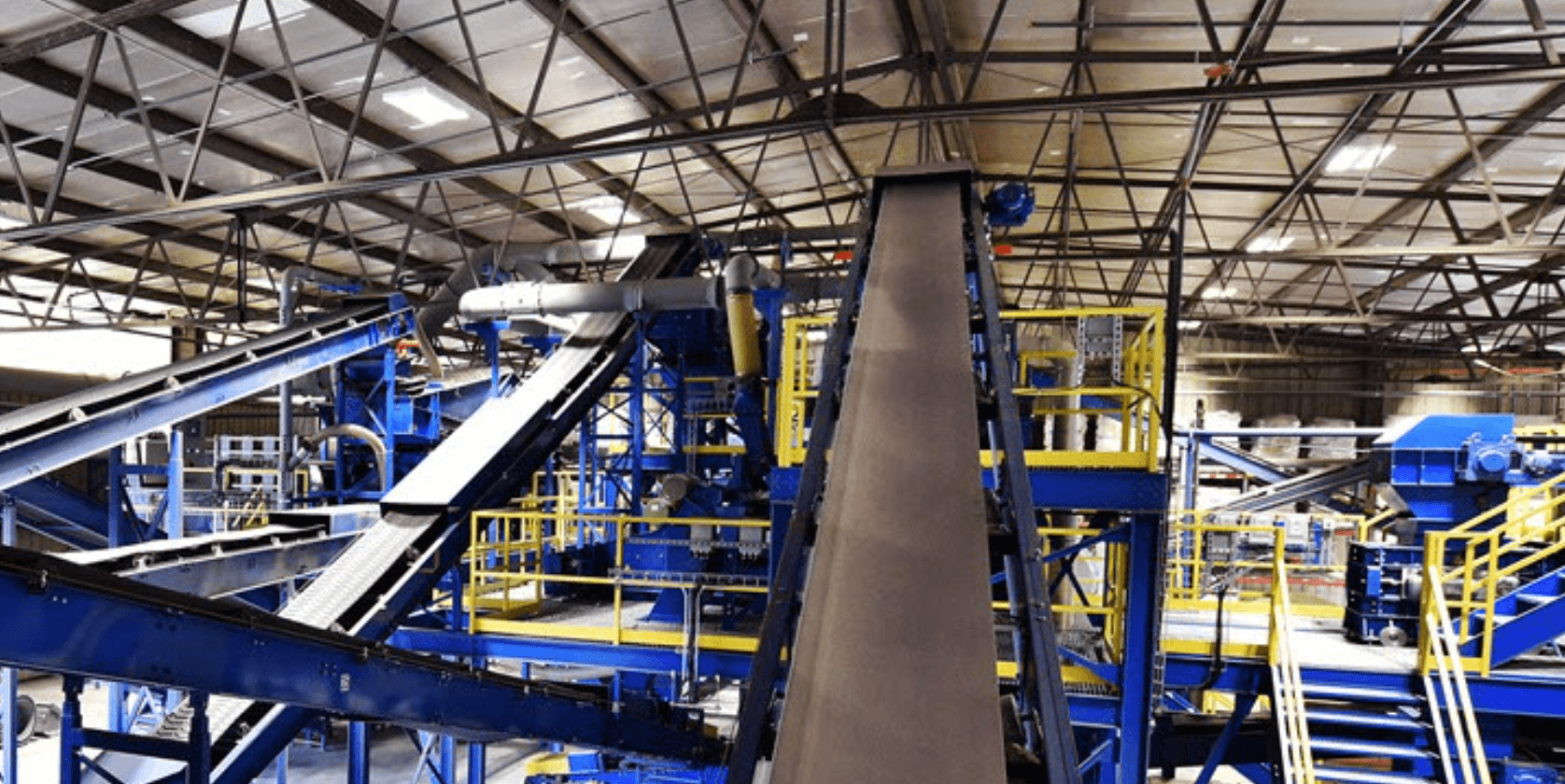

Blackhawk Equipment Finds Compressed Air Efficiency for Momentum Recycling.

As the first bottle-to-bottle recycling facility in the state, Momentum Recycling in Broomfield is a significant asset supporting the environmentally responsible mindset that has become a hallmark of Colorado lifestyles. Glass recycling can reduce about 5 percent of the waste stream which means less landfill space is needed. Thanks to Momentum, 85 percent of recycled glass in Colorado goes back into new bottles.

Yet, recycling glass is no simple task. The process is a complicated industrial procedure which includes several filtering steps of materials.

That’s the theme realized by Momentum after the plant had been open about a year. Questions were raised about the performance of their compressed air equipment. They turned to Blackhawk Equipment, and a compressed air audit was performed for the facility. The Blackhawk audit team quickly realized tremendous opportunities to optimize for both equipment performance and energy savings. Blackhawk was able to get Momentum Recycling a significant rebate through the Xcel Energy Rebate Program. Here are the main updates and adjustments they made through our recommendations and service:

- Replacing a pair of 100 horsepower constant speed machines, with a new Sullair V250S-250L, variable speed drive, variable capacity control 250 horsepower compressor. The combination of variable speed drive and variable capacity control optimize energy efficiency and allow the machine to operate at peak efficiencies at part load conditions.

- A blower purge desiccant dryer. Reducing overall compressed air demand by eliminating costly purge air to regenerate the offline tower by utilizing heated ambient air from a smaller HP blower.

- A much smaller reciprocating compressor to operate the fire suppression system. Allowing the larger 100 Horsepower machines to be shut off during non-production weekends, saving tremendous amounts of energy.

Metal Beverage Container Company - Colorado – Saved 931 kW, Rebate of $684,000

This customer wanted Blackhawk Equipment to conduct a compressed air system audit, due to our expertise in the metal beverage industry. They had just finished a project with another vendor that ended up with no energy savings or incentive, but still believed efficiency improvements and energy savings were possible.

This customer wanted Blackhawk Equipment to conduct a compressed air system audit, due to our expertise in the metal beverage industry. They had just finished a project with another vendor that ended up with no energy savings or incentive, but still believed efficiency improvements and energy savings were possible.

Blackhawk Equipment worked with Xcel Energy and decided the path forward included a “self direct” program due to the higher incentives offered. Working with Xcel, Blackhawk developed a Measurement and Verification plan specific to the customer and that would satisfy Xcel Energy’s requirements.

The plant ran 7 - 600 HP centrifugal compressors and 1- 1000 HP compressor. The units were very old and inefficient. The controls of the individual machines did not efficiently work together, but given the age of the equipment, new controls and massive overhauls were not ideal.

After measurement and data analysis, we recommended a single 1,750 HP compressor to replace the 7-600 HP units. The project was accepted and approved by the customer and Xcel energy. The customer made a few process changes and the new compressor was installed.

We completed a post-project measurement and verification process and discovered the customer was saving in excess of 931 KW (1,247 Horsepower). Xcel Energy paid out an incentive of $684,000.00 on this project.

Garlock Pipeline Technologies – Equipment Rebate, <3 year Project Payback

The customer’s existing system was out of capacity, so they called on Blackhawk Equipment to conduct an air audit and recommend an energy efficient replacement compressor to meet their growing compressed air needs.

The existing air system supplied air for the manufacturing lines located in the GPT industrial complex for the manufacturing of piping flange gaskets. The system was comprised of one 30hp fixed speed oil flooded rotary screw compressor. The system has one compressor room which also contained an air dryer and receiver tank. Observed end uses were regulated, and pressures varied.

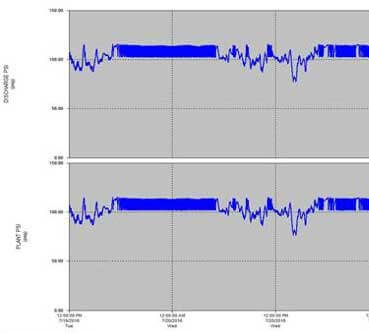

The air audit returned the following data:

- The current system uses 135,500kwh/yr.

- Dew point of the system remained

- System pressure was erratic during periods of saturation, indicating a lack of capacity.

Based on the findings of the audit of the compressed air system Blackhawk Equipment recommended the following:

- Compressor – additional supply needed to address demand events

- New air dryer to match larger compressor

- Fix a minimum of 50% of leaks identified, refer to leak detection study.

- Replace rubber hose with hard pipe. Rubber hose has a pressure drop ~4 times greater than that of hard pipe. This elevated pressure drop requires regulators to be set at a higher pressure in order to produce the required discharge pressure at the point of use than typically required. It also inflates the true plant minimum pressure requiring compressors to maintain a higher system pressure. In addition, the life span of rubber hose is significantly less than that of hard tubing. This can be seen in the results of the leak walkthrough as there were leaks directly correlating to the aging and failure of the rubber tubing.

- Investigate machine pressure reduction. It is recommended that all production machines operate at the minimum required pressure.

- Due to the extensive amount of polyurethane tubing on the machines used in the manufacturing process, it is recommended that a quarterly leak maintenance program be implemented to actively repair leaks on the production equipment.

- A significant amount of compressed air blowguns are used throughout the plant. It is recommended that blowguns have regulators installed upstream to limit pressure to 35 psig. This pressure is sufficient for blowing metal/plastic chips from machinery.

Upon repair of the leaks found in the system and the installation of the 50hp VSD compressor, Blackhawk Equipment was able to secure an Xcel Rebate of $6,137 as an incentive to purchase the VSD compressor and provide a 2.93 year payback of the new VSD compressor in energy savings. All of this was accomplished by stabilizing system pressure and increasing the minimum pressure of the plant during periods of peak flow.