Anatomy of a Modern Air-End: What Makes a Rotary Screw Compressor Tick

09/24/2025

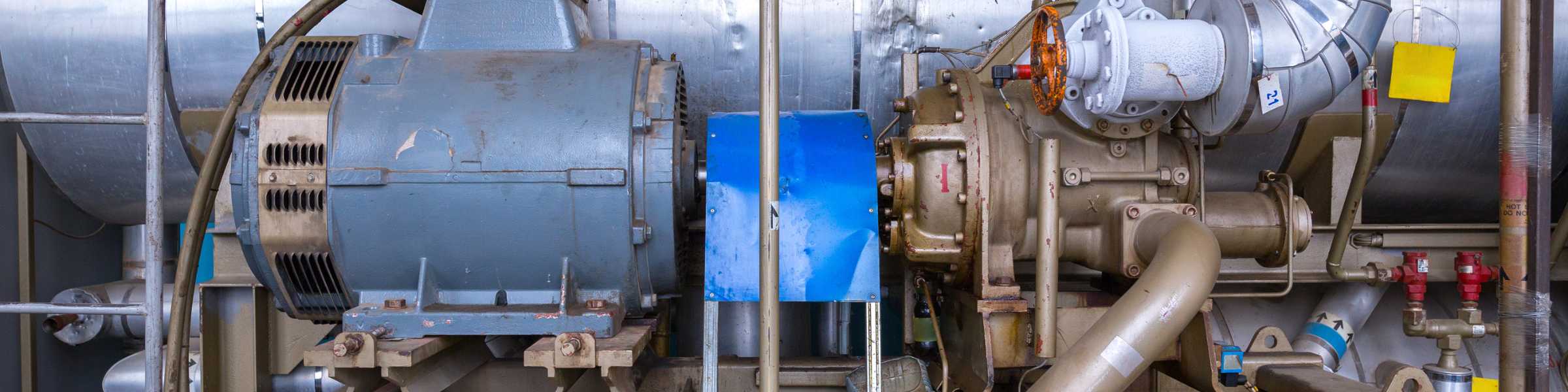

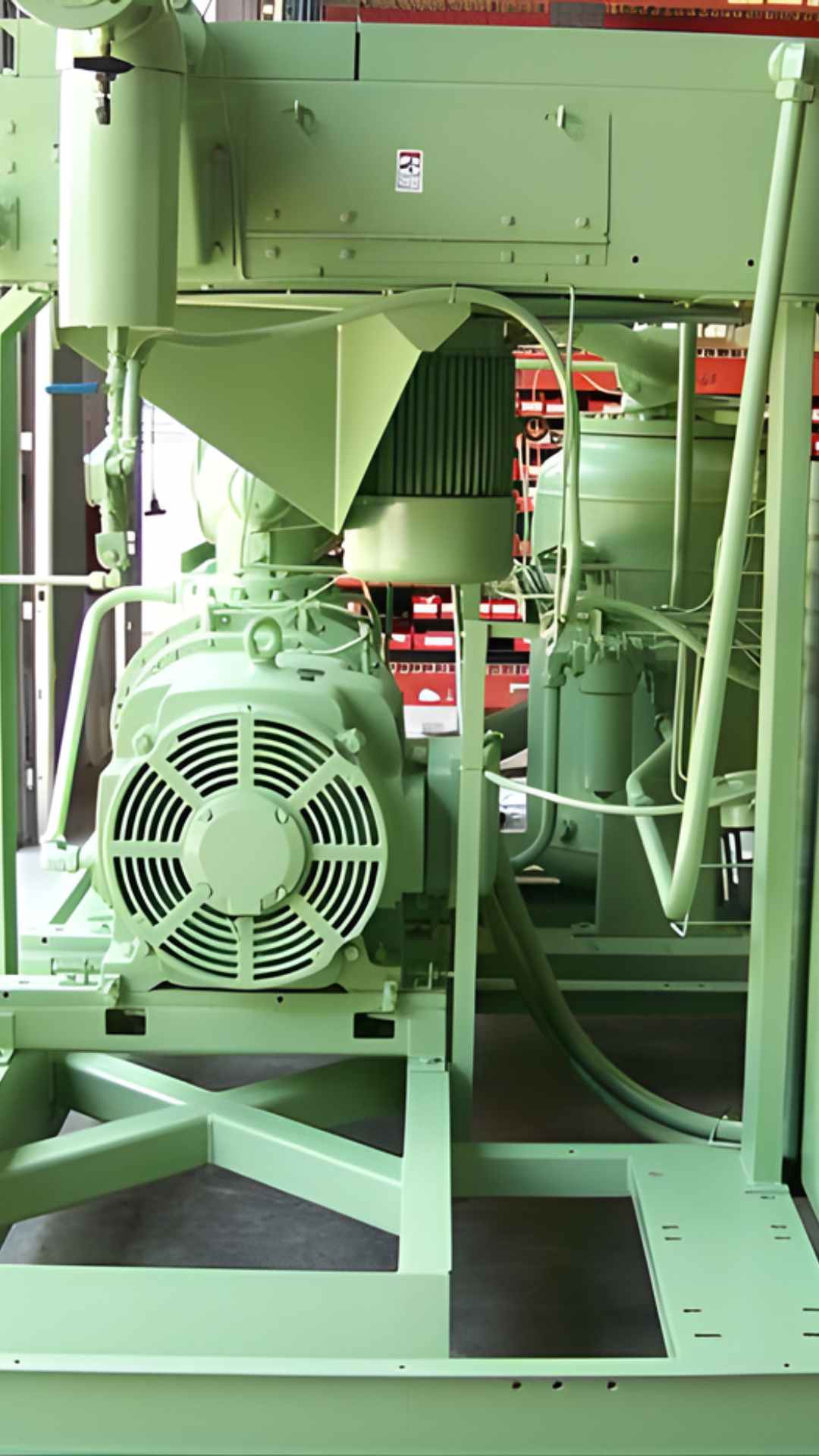

In any rotary screw air compressor, regardless of its size or manufacturer, there is one component that stands as its undisputed heart: the air-end. While the motor provides the power and the controller provides the brains, the air-end is where the fundamental work of compression actually happens. It is a marvel of precision engineering, where massive forces are managed within microscopic clearances to efficiently transform ambient air into a powerful utility. Understanding the anatomy of this critical component is key to appreciating what makes a compressor reliable, efficient, and durable. As of September 2025, air-end designs are more advanced than ever. At Blackhawk Equipment, our expertise is built on a deep, hands-on understanding of these core components, especially the legendary air-ends from partners like Sullair. Let's take a look inside.

What is an Air-End and What Does It Do?

The air-end is the positive-displacement rotary unit at the center of the compressor. Its sole purpose is to take in atmospheric air, trap it, reduce its volume, and discharge it at a higher pressure. In an oil-flooded design, it performs this function while being continuously lubricated, cooled, and sealed by a flow of specialized oil. The basic process is elegant: air is drawn into the inlet port and fills the voids between two intermeshing helical rotors. As the rotors turn, they progressively reduce the volume of these voids, squeezing the air and increasing its pressure as it moves along their length toward the discharge port.

The Key Components: A Look Inside a Modern Air-End

While simple in concept, the modern air-end is a symphony of precisely engineered components working in perfect harmony.

The Rotors: The Stars of the Show:

-

Male and Female Rotors: The core of the air-end consists of two precisely machined helical rotors: a "male" rotor with lobes (typically four or five) and a "female" rotor with a corresponding number of flutes or valleys. The male rotor is typically driven by the motor, and it, in turn, drives the female rotor, often via a thin film of oil.

-

The Critical Rotor Profile: The specific shape, or "profile," of these lobes and flutes is a manufacturer's most closely guarded secret and a primary driver of efficiency. Decades of research and development have gone into creating advanced, asymmetric rotor profiles. The goal is to minimize the size of the "blow-hole"—a leakage path that exists between the meshing rotors—and to ensure the compression process is as smooth and efficient as possible. A superior rotor profile directly translates to more CFM of air for every kW of energy consumed.

-

[Precision Machining: The performance of the rotors depends on incredibly tight manufacturing tolerances. The clearances between the rotors themselves, and between the rotors and the housing, are often measured in thousandths of an inch (microns). This precision is what allows the rotors to create an effective seal without making metal-to-metal contact.

The Bearings: The Unsung Heroes of Reliability:

The rotors spin at thousands of RPM under immense pressure. This creates powerful radial (sideways) and axial (thrust) loads that must be m anaged flawlessly. The bearing arrangement is therefore absolutely critical to the air-end's longevity. Bearing failure is the leading cause of air-end failure.

anaged flawlessly. The bearing arrangement is therefore absolutely critical to the air-end's longevity. Bearing failure is the leading cause of air-end failure.

-

Radial Bearings: These bearings, often cylindrical or spherical roller bearings, support the weight of the rotors and handle the radial forces generated as the rotors push against each other.

-

Thrust Bearings: As air is compressed, a powerful axial force pushes the rotors towards the discharge end of the housing. This force is handled by specialized thrust bearings, such as tapered roller bearings or angular contact ball bearings, which are designed to absorb these immense loads. The quality and design of the thrust bearing arrangement are often key differentiators between standard and premium air-ends.

The Housing: The Foundation of Precision:

The rotors and bearings are all contained within a heavy-duty housing, typically made of high-grade cast iron. The housing's role is to provide a rigid, stable foundation that can maintain the precise alignment and clearances of all internal components, even as the unit heats up to operating temperature. The interior surfaces are machined to the same high tolerances as the rotors themselves.

Shaft Seals: Keeping the Lubricant Contained:

-

A critical component at the drive end of the air-end is the shaft seal. Its job is to prevent the high-pressure lubricant from leaking out along the motor drive shaft while preventing outside contaminants from entering. Failure of this seal can lead to significant oil loss and potential system contamination.

The Drive Method's Impact on the Air-End

-

Belt-Drive: The motor connects to the air-end's drive shaft via a belt and pulley system. This arrangement allows for easy changes to the compressor's speed ratio but introduces belts as a maintenance item and can place high radial loads on the air-end's drive-side bearing.

-

Direct-Drive: The motor is coupled directly to the air-end's drive shaft. This provides the most efficient transfer of energy (no belt slippage losses), eliminates belt maintenance, and often results in a quieter, more compact design. It's a hallmark of many premium industrial compressors.

Why Air-Ends Fail and The Rebuild Process

Common Causes of Failure:

-

Bearing Failure: This is the most common cause. It can result from lubricant conta

mination, lubricant breakdown (varnish), excessive vibration (misalignment), or simply reaching the end of the bearing's calculated L10 design life.

mination, lubricant breakdown (varnish), excessive vibration (misalignment), or simply reaching the end of the bearing's calculated L10 design life. -

Rotor Contact: This is a catastrophic failure, almost always caused by a prior bearing failure. As the bearings wear, they allow the rotors to deflect and make contact with each other or the housing, causing severe damage.

-

Overheating: Chronic overheating, caused by issues like clogged coolers or poor ventilation, will drastically accelerate lubricant breakdown and lead to premature bearing failure.

The Rebuild Process in Brief:

-

When an air-end fails, it can often be professionally rebuilt. This is a highly specialized process that involves a complete disassembly, meticulous cleaning (often including chemical stripping of varnish), and a thorough inspection of the rotors and housing. All bearings and seals are replaced, and the unit is carefully reassembled in a clean environment to restore the original factory clearances and performance.

Blackhawk and Sullair: A Legacy of Air-End Excellence

At Blackhawk Equipment, our partnership with Sullair is built on a shared commitment to reliability, and the Sullair air-end is a testament to that commitment. Sullair has a world-renowned reputation for engineering and building some of the most robust and durable air-ends in the industry. Their focus on conservative bearing designs, efficient rotor profiles, and quality manufacturing has resulted in air-ends that are known for their exceptionally long service life. Our factory-trained technicians have the deep expertise required to properly service, diagnose, and manage the lifecycle of these critical components, ensuring our customers get the maximum value and uptime from their investment.

Conclusion: Respecting the Heart of Your Compressor

The air-end is far more than just a component; it is the functional core of your rotary screw compressor. Its precision-engineered rotors, robust bearings, and rigid housing all work in concert to deliver the compressed air that powers your plant. Understanding the anatomy of this critical unit highlights the importance of using high-quality lubricants, adhering to proper maintenance schedules, and monitoring for early signs of wear. A healthy air-end means a healthy, efficient, and reliable compressed air system.

Contact Blackhawk Equipment for expert service on your compressor's air-end or to learn more about the superior engineering behind the Sullair compressors we proudly offer. Let us help you protect the heart of your system.