Compressed Air Safety Beyond the Basics: Addressing Risks from High Pressure, Noise, and Hot Surfaces

06/05/2025

In nearly every industrial facility, compressed air is so fundamental and ubiquitous that its presence is often taken for granted. This familiarity can unfortunately lead to complacency. While most safety programs cover the obvious rule—never use compressed air to clean clothing or skin—the most significant dangers associated with these powerful systems are often less apparent. As engineers and maintenance professionals, our duty of care requires a deeper understanding of the inherent risks found in and around the compressor room. As of June 2025, ensuring a safe working environment is a top priority, driven by both regulation and corporate responsibility. At Blackhawk Equipment, we believe that a reliable system is a safe system. This guide will go beyond the basics to address the three primary hazards of compressed air systems: high pressure, noise, and heat.

The High-Pressure Hazard: The Dangers of Stored Energy

The power of compressed air comes from storing a large volume of air in a small space, creating immense potential energy. When this energy is released in an uncontrolled manner, the results can be devastating.

-

The Risk of Air Injection:

- This is a severe medical emergency that is often underestimated. Compressed air, even at pressures as low as 15 PSI (1 bar), can penetrate the skin. If air enters the bloodstream, it can create an air embolism—an air bubble that can travel to the heart or brain, causing a heart attack, stroke, or death. This is why using compressed air for cleaning skin is strictly forbidden.

-

Uncontrolled Energy Release:

- Catastrophic Hose Whipping: A pressurized air hose that fails or becomes disconnected from its fitting can whip around with incredible force, causing serious injury or property damage. The energy released is powerful enough to break bones or cause fatal blunt-force trauma.

- Component and Receiver Tank Failure: An air receiver tank contains an enormous amount of stored energy. A catastrophic failure of a tank due to corrosion or damage can have the explosive force of a bomb. This underscores the absolute necessity of using only ASME-certified pressure vessels and ensuring they are regularly inspected and protected by a correctly sized and functional pressure relief valve.

-

Pressure Hazard Mitigation Strategies:

- Never point an air nozzle at anyone, including yourself.

- For cleaning tasks, only use OSHA-compliant air nozzles that are engineered to reduce the pressure to below 30 PSI when dead-ended.

- Always install safety check valves (velocity fuses) and whip checks on hose connections, especially for larger diameter hoses, to prevent hose whipping in case of a failure.

- Implement a regular inspection schedule for all air hoses, couplings, and fittings, immediately replacing any that show signs of wear, abrasion, or cracking.

- Verify that all pressure vessels have a functioning pressure relief valve that is tested and certified according to local regulations.

The Noise Hazard: A Silent Threat to Long-Term Health

Compressor rooms are consistently among the loudest areas in an industrial plant. Noise levels from large industrial compressors can easily exceed OSHA's action level of 85 dBA and the permissible exposure limit of 90 dBA over an 8-hour time-weighted average (TWA).

-

Sources of Compressor Room Noise:

- The noise is a composite from multiple sources: the powerful suction at the compressor intake, the operation of the electric motor and cooling fans, the mechanical noise from the compressor unit (air end), vibrations transmitted through piping and the floor, and the high-frequency hiss of air leaks.

-

The Irreversible Damage:

- Unlike many other injuries, Noise-Induced Hearing Loss (NIHL) is permanent and irreversible. Prolonged or repeated exposure to high noise levels damages the delicate hair cells in the inner ear. The effects are cumulative and often go unnoticed until significant, life-altering damage has occurred.

-

Applying the Hierarchy of Controls for Noise:

The most effective way to manage noise is to follow the standard hierarchy of controls:- Engineering Controls (Most Effective): The best approach is to reduce noise at its source. This includes purchasing modern compressors with sound-dampening enclosures, installing intake and discharge silencers, using acoustic insulation on room walls and ceilings, and ensuring pipes are properly clamped and isolated to prevent vibration and rattling.

- Administrative Controls: This involves changing work practices. Limit the amount of time personnel are required to spend in high-noise areas. Post clear warning signs at all entrances to the compressor room indicating that hearing protection is mandatory.

- Personal Protective Equipment (PPE) (Least Effective, but Essential): While PPE is considered the last line of defense, it is absolutely essential. Mandate the use of properly rated hearing protection (earplugs and/or earmuffs) for any individual entering the designated high-noise area.

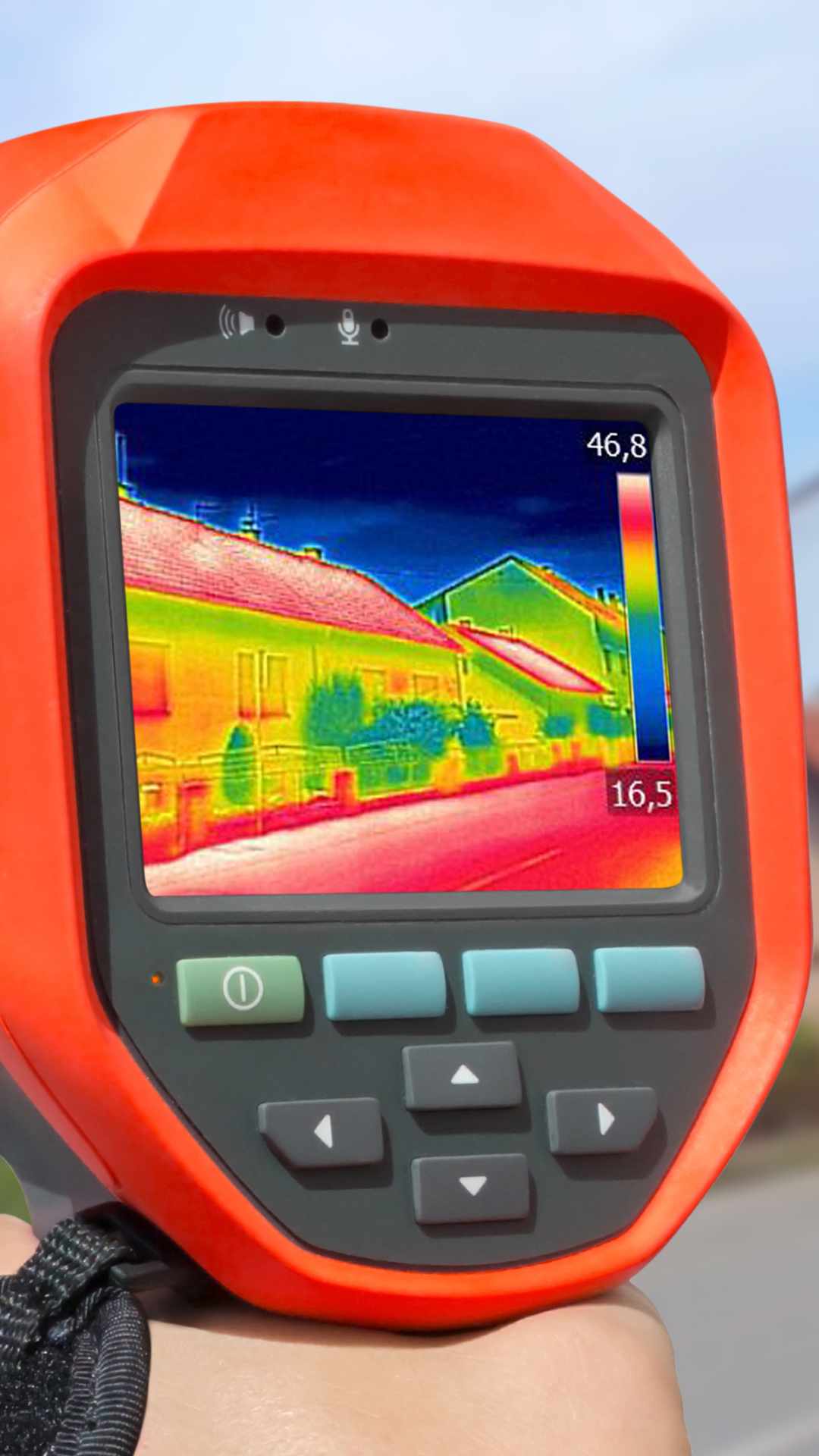

The Thermal Hazard: Managing Hot Surfaces, Fluids, and Air

The law of thermodynamics is unavoidable: compressing air generates a tremendous amount of heat. Surfaces and fluids within the compressor system can reach temperatures high enough to cause severe, instantaneous burns.

-

Identifying High-Temperature Zones:

- Be aware of the primary hot spots: the compressor air end itself, the discharge piping (which can easily exceed 350°F or 177°C), oil lines, oil coolers, and the main electric motor.

-

Risks Beyond Burns:

- Hot surfaces can act as an ignition source if flammable materials, solvents, or vapors are present in the area. Furthermore, hot compressor lubricant can spray out with significant force if a line is opened on a system that has not been properly depressurized and allowed to cool, creating both a burn and an injection hazard.

-

Thermal Hazard Mitigation Strategies:

- Guarding and Insulation: Install physical guards or cages to prevent accidental contact with hot surfaces like motors and compressor units. Insulate high-temperature discharge piping and other components in areas where personnel may need to work.

- Prominent Warning Signage: Clearly label all hot surfaces and pipes with standardized high-temperature warning signs.

- Strict Lockout/Tagout (LOTO) Procedures: This is non-negotiable. Maintenance must never be attempted on a running or hot compressor. A comprehensive LOTO procedure must be followed to ensure the machine is completely de-energized electrically, fully depressurized, and given adequate time to cool down before any service work begins.

Creating a Culture of Safety in the Compressor Room

A truly safe environment is built on a foundation of sound engineering and vigilant procedures. Best practices for the compressor room include:

- Controlled Access: The compressor room should be treated as a restricted area. Only trained and authorized personnel should be allowed entry.

- Excellent Housekeeping: The area must be kept clean, well-lit, and free of clutter. Storing flammable materials or obstructing ventilation pathways in a compressor room is extremely dangerous.

- Comprehensive Training: All personnel who operate or maintain the compressed air system must receive regular, documented training on the specific hazards—pressure, noise, heat, and electrical—and the procedures to mitigate them, especially LOTO.

Blackhawk Equipment's Commitment to Safe Operations

Our commitment to our customers extends beyond supplying efficient and reliable equipment. We prioritize safety in every stage. We achieve this by:

- Supplying modern equipment from world-class manufacturers that incorporates advanced safety features like protective enclosures, safety shutdowns, and integrated guards.

- Providing professional installation that adheres to best practices for safety, such as proper pipe support, ventilation design, and electrical work.

- Ensuring our own factory-trained technicians follow rigorous safety protocols, including strict LOTO procedures, whenever they are on-site for service and maintenance.

Conclusion: Making Safety a Core Component of Your Air System

A safe industrial facility is a productive and profitable one. This requires looking beyond the common-knowledge safety tips and cultivating a deep respect for the inherent power and hazards of core utility systems. By systematically addressing the risks of high pressure, noise, and heat through a combination of engineering controls, robust administrative procedures, and proper use of PPE, you can create a truly safe working environment around your compressed air equipment. Safety isn't an afterthought; it's a critical component of a well-managed system.

Contact Blackhawk Equipment to partner with a team that values safe operations as much as it values efficiency and reliability. Let us help you ensure your compressed air system is a powerful asset, not a potential liability.