Emergency Procedure: What to Do Immediately After a Catastrophic Compressor Separator Failure

10/01/2025

It is one of the most dreaded failure scenarios in any industrial plant. You have a catastrophic failure of the air/oil separator element in your rotary screw compressor, and suddenly, a massive volume of hot lubricant is violently discharged into your entire compressed air network. This is not a minor maintenance issue; it is a full-blown industrial emergency that can shut down production for days, cause tens of thousands of dollars in damage to downstream equipment, and contaminate your entire piping system. While rare, this event requires a calm, swift, and methodical response. The actions you take in the first 60 minutes are absolutely critical to mitigating the long-term damage. At Blackhawk Equipment, our expert service team has managed these crises. This guide provides a clear, step-by-step emergency procedure for what to do in the immediate aftermath of a separator failure.

Understanding the Catastrophe: What Is a Separator Failure?

In a normal oil-flooded rotary screw compressor, the air/oil separator is a highly engineered filter designed to remove fine, aerosolized oil droplets from the compressed air before it leaves the compressor package. A high-quality separator can achieve residual oil content of just 2-3 parts per million (ppm).

The Failure Mechanism:

A catastrophic failure is not a slow degradation; it's a sudden event. The filter media of the separator element can rupture, tear, or completely collapse. This is often caused by a massive and sudden pressure differential across the element, which can result from a clogged scavenge line, a malfunctioning minimum pressure check valve, or, most commonly, the use of a poor-quality, non-OEM "will-fit" separator element that cannot withstand the system's operational stresses.

The Immediate Consequence: Massive Oil Carryover:

The instant the element ruptures, a path of least resistance is created. The high-pressure air violently forces a significant portion of the compressor's oil sump directly past the failed element and into your plant's air piping. This is not a fine mist; it's often a bulk transfer of liquid oil flooding the entire system.

The First Hour: Your Step-by-Step Emergency Action Plan

Your immediate response is critical. Follow these steps precisely.

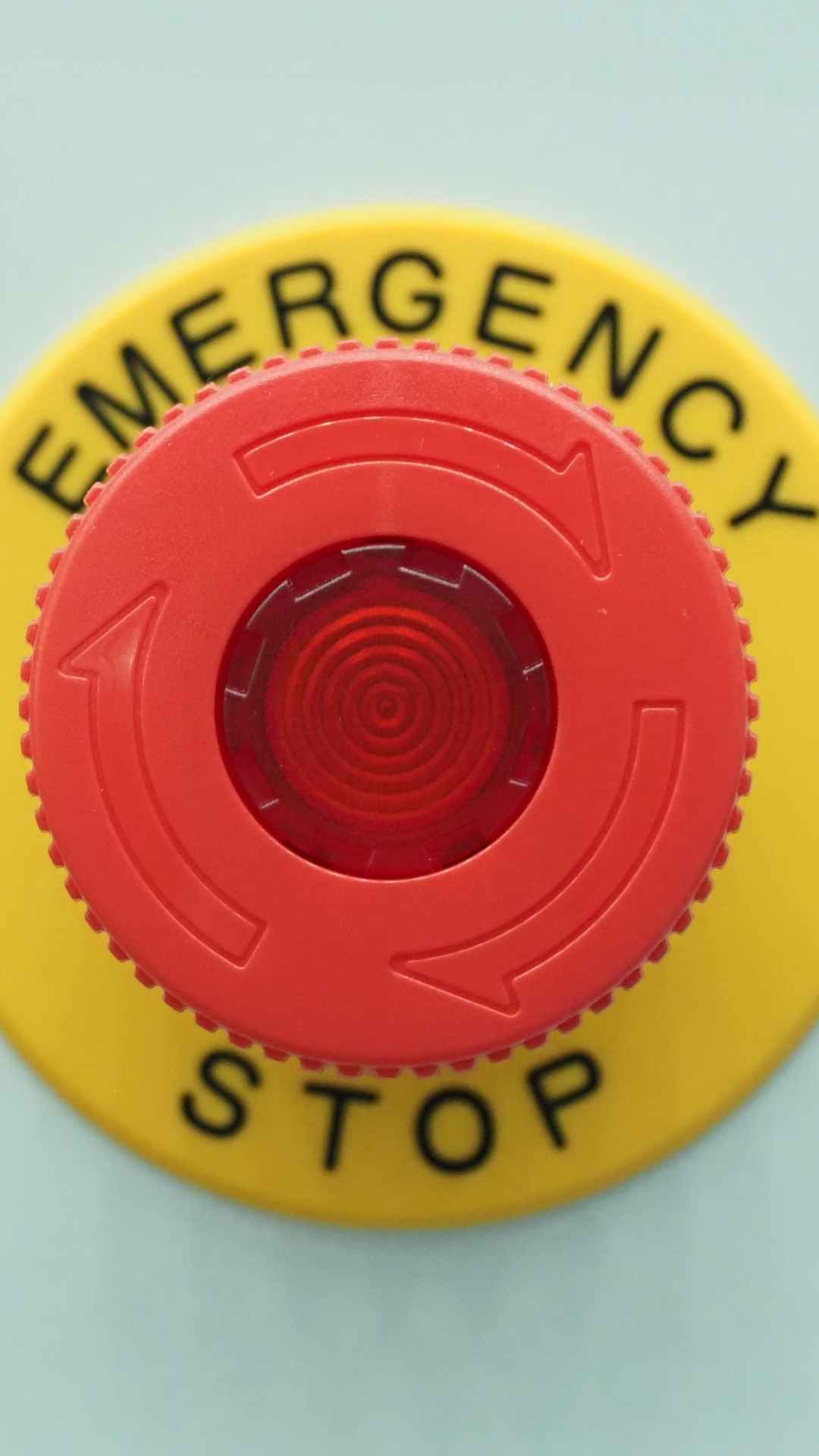

Step 1: SHUT DOWN THE COMPRESSOR IMMEDIATELY:

This is the absolute first and most important action. Do not hesitate. Hit the emergency stop button for the affected compressor. Every second the compressor continues to run, it is pumping more oil into your system, compounding the damage exponentially.

Step 2: ISOLATE THE AFFECTED COMPRESSOR AND SYSTEM:

Immediately close the main air outlet valve (the isolation valve, typically a ball or gate valve) located on the discharge pipe of the compressor. This accomplishes two things: it prevents any more oil from migrating into the plant air header, and it prevents the entire system from depressurizing back through the failed compressor.

Step 3: NOTIFY KEY PERSONNEL:

Communicate the situation clearly and calmly. Alert the plant manager, maintenance supervisor, and the heads of all production departments that rely on compressed air. Inform them of an immediate and likely extended shutdown of the compressed air utility.

Step 4: ASSESS THE IMMEDIATE IMPACT (VISUALLY):

Walk the plant floor. Look for visible signs of the oil contamination. You may see oil leaking from the exhaust ports of pneumatic valves, dripping from air tools, or pouring out of automatic filter drains. This will help you understand the extent of the contamination.

Step 5: DO NOT, UNDER ANY CIRCUMSTANCES, RESTART THE COMPRESSOR:

There may be pressure to get the system back online quickly. Resist this. Restarting the compressor without a full diagnosis and repair will cause severe damage to the compressor itself and will only continue to pump oil into your already contaminated system. The machine is offline until it is professionally serviced.

Step 6: CALL YOUR EXPERT COMPRESSED AIR SERVICE PARTNER:

This is not a DIY fix. A catastrophic separator failure requires specialized knowledge for both the repair and the extensive cleanup. Your first phone call after shutting down and isolating the system should be to a trusted service partner like Blackhawk Equipment.

The Recovery Phase: A Systematic Approach to Cleanup and Repair

Once the immediate crisis is contained, the recovery process begins. This is a methodical but labor-intensive process that must be managed by experienced technicians.

The Compressor Itself:

-

Root Cause Analysis (RCA): The first step for the service technician is to perform an RCA to determine why the separator failed. This is critical to prevent a recurrence.

-

Decontamination and Repair: This involves completely draining the oil sump, removing the failed separator and all other filters (oil, inlet), thoroughly cleaning the separator tank and all internal piping, and inspecting related components like the scavenge line and minimum pressure check valve. Only then can a new, genuine OEM separator be installed.

The Contaminated Downstream Air System:

-

Draining Bulk Oil: Manually open all drains on air receivers, filter bowls, and drop legs throughout the plant to drain as much of the liquid oil as possible.

-

Replacing ALL Filter Elements: This is non-negotiable. Every single coalescing and particulate filter element in your entire plant is now saturated with oil and has been destroyed. They cannot be cleaned or salvaged. They must all be replaced.

-

Cleaning Piping and Receivers: The wet air receiver will be heavily contaminated and will need to be isolated and professionally cleaned. The piping network itself presents the biggest challenge. This may involve flushing the system with specialized, non-toxic industrial degreasers, followed by a thorough purge with clean, dry air (often supplied by a temporary rental compressor). In critical industries like food and beverage, contaminated piping sections may need to be disassembled for manual cleaning or even completely replaced.

-

Servicing End-Use Equipment: Every pneumatic tool, cylinder, valve, and actuator that was exposed to the oil must be individually inspected, cleaned, and potentially rebuilt or replaced.

Prevention: The Best Insurance Policy

-

Use ONLY Genuine OEM Separator Elements: Air/oil separators are not simple filters; they are highly engineered components designed to withstand specific pressures, temperatures, and chemical compositions. Using cheaper "will-fit" elements is the leading cause of premature and catastrophic separator failure. The minor cost savings are not worth the immense risk.

-

Adhere to Strict Maintenance Schedules: Replace separator and oil filter elements according to the manufacturer's recommended service intervals, without exception.

-

Monitor Differential Pressure: A sharp and sustained increase in the pressure drop across the separator is a key warning sign that it is becoming clogged and is under excessive stress. This should be investigated immediately.

How Blackhawk Equipment Manages This Crisis

In an emergency like a separator failure, you need a partner who is calm, experienced, and responsive. Blackhawk Equipment provides critical support by:

-

Deploying Rapid-Response Service: Our expert technicians can be on-site quickly to diagnose the root cause and begin the repair process.

-

Providing Rental Compressors: We can promptly supply a rental air compressor to get your most critical production lines back up and running with clean air while your main system is being decontaminated.

-

Managing the Repair and Cleanup Process: Our team can perform the expert repair of the compressor and provide guidance and services for the extensive downstream cleanup process.

-

Supplying Genuine OEM Parts: We provide genuine OEM separator elements and filters from manufacturers like Sullair, ensuring the repair is done right and is built to last.

Conclusion: A Plan for the Unplannable

A catastrophic compressor separator failure is a major industrial crisis. While prevention is always the best strategy, having a clear and concise emergency action plan is the next best thing. A swift, methodical response focused on immediate shutdown, isolation, and calling in expert help can significantly mitigate the long-term damage, cost, and downtime. By understanding the risks and preparing a response, you can turn a potential plant-wide disaster into a manageable (though serious) recovery operation.

We recommend you save Blackhawk Equipment's service contact information where it is easily accessible. In a crisis like this, a fast call to the right partner can make all the difference.