Understanding Master Controller Logic: How Advanced Sequencing Optimizes a Multi-Compressor System

07/11/2025

Many industrial facilities rely on multiple air compressors to meet their production demands. It’s a common sight: a compressor room with several powerful machines lined up, ready to work. However, a critical question engineers must ask is: are these machines working together as a cohesive system, or are they working against each other? Without a central "brain" to coordinate their actions, a multi-compressor system is like an orchestra without a conductor—full of powerful instruments playing out of tune, creating chaos instead of harmony. This chaos results in significant energy waste, unnecessary wear and tear, and unstable system pressure. That central brain is the master controller, or sequencer. At Blackhawk Equipment, we specialize in designing and implementing these sophisticated control systems. This guide will take you beyond the surface to explain the core logic of how a master controller transforms a collection of individual machines into a single, highly efficient, and optimized compressed air utility.

The Common Problem: Inefficient "Cascading" and Uncoordinated Control

In facilities without a master controller, the most common control method is the "cascading pressure band." In this setup, each compressor has its own internal controller and is set to a slightly different pressure range. For example, Compressor 1 might be set to 110-120 PSI, Compressor 2 to 105-115 PSI, and Compressor 3 to 100-110 PSI. The idea is that as pressure drops, the next compressor in the cascade will turn on. While simple to set up, this method is notoriously inefficient for several reasons:

-

Unnecessary High Pressure:

To prevent the last compressor in the cascade from short-cycling, the overall system pressure is often kept artificially high. Since every 2 PSI reduction in pressure saves about 1% in energy costs, this elevated pressure represents a constant source of energy waste.

-

Inefficient Compressor Selection:

The cascade method has no intelligence. It doesn't know which compressor is the most efficient to run for a given demand. It might run two smaller, less efficient compressors when one larger, more efficient unit could handle the load better.

-

Excessive and Wasteful Cycling:

The lead compressor often cycles frequently between loaded and unloaded states. A rotary screw compressor still consumes a significant amount of power (often 25-35% of full load power) when running unloaded but producing no air. This is pure waste.

-

Mismanagement of VSD Compressors:

A common mistake is to place a Variable Speed Drive (VSD) compressor in a cascade. This often results in the VSD running at 100% speed (its least efficient point) acting as a fixed-speed machine, while other fixed-speed compressors cycle inefficiently beside it. This completely negates the energy-saving purpose of the VSD.

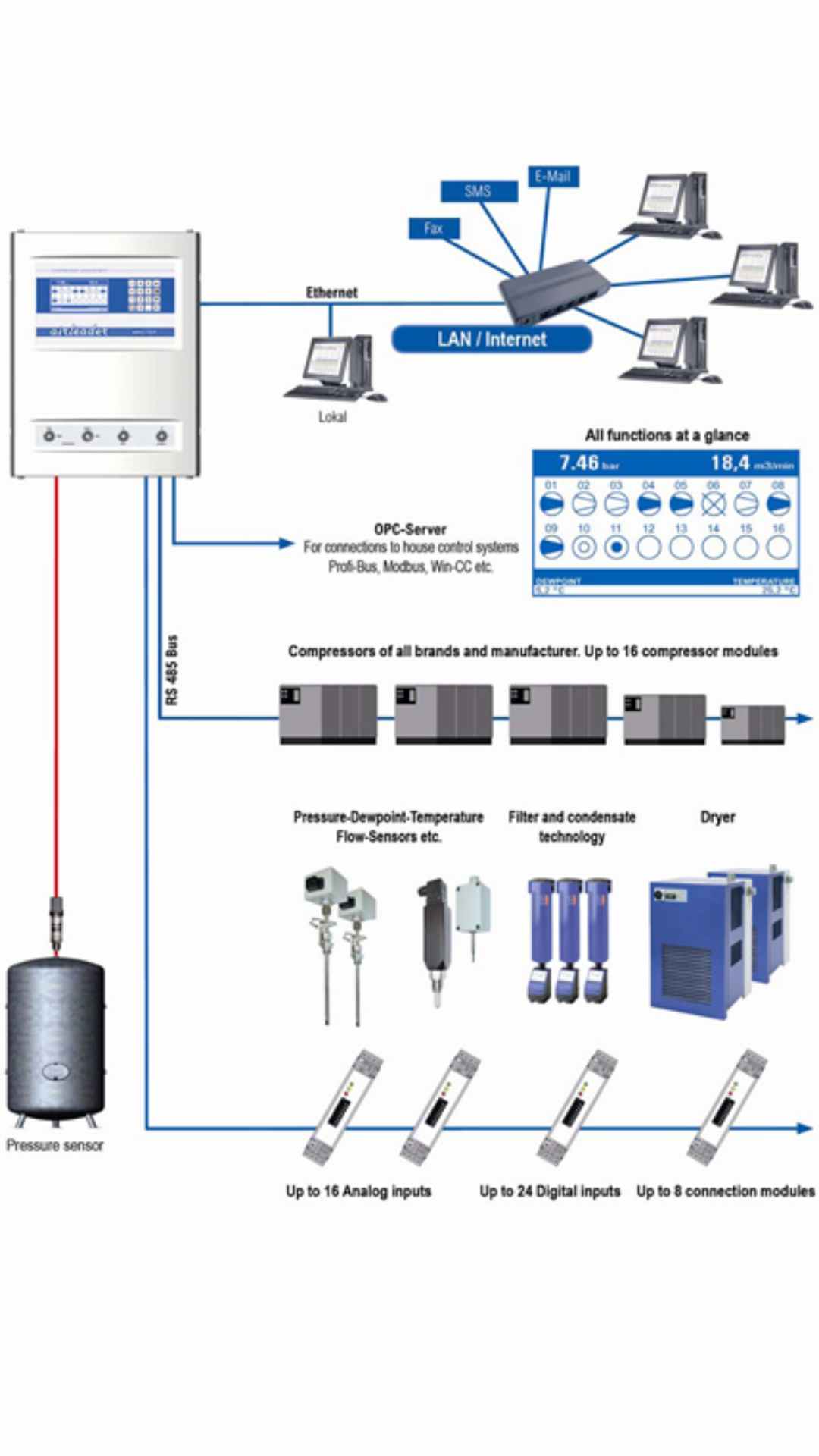

The Solution: The Master Controller as the System's Conductor

A master controller is a centralized, microprocessor-based system that acts as the single point of intelligence for the entire compressor room. It constantly monitors the total plant air demand by reading from a single, strategically placed pressure transducer in the main air header. Based on this real-time demand data, it intelligently selects which compressors to start, stop, load, or unload to meet the demand precisely, all while maintaining a much tighter, lower pressure band for the entire system. It transforms the compressor room from a group of individual machines into one integrated, responsive, and highly efficient system.

Deconstructing the Logic: How Advanced Sequencing Achieves Optimization

Modern master controllers, like those offered by Sullair and other leading manufacturers, employ sophisticated logic to achieve peak performance.

-

Centralized, Tight Pressure Band Control:

-

The first thing a master controller does is eliminate the inefficient pressure cascade. It establishes a single, tight pressure band for the entire system (e.g., 98-102 PSI). By operating the entire plant at a lower and more stable pressure, it generates immediate energy savings.

-

-

Demand-Based, Intelligent Compressor Selection:

-

The controller is programmed with the specific capacity (CFM) and efficiency (kW/CFM) of every compressor in the system. When plant demand changes, the controller runs simulations to determine the most energy-efficient combination of compressors to meet that new demand. It might choose to bring a large, efficient base-load machine online instead of two smaller ones, a decision a simple cascade system could never make.

-

-

Hour Balancing for Equalized Wear:

-

To prevent one compressor from accumulating all the run hours while others sit idle, the controller can be programmed to automatically rotate the lead/lag compressor roles. This "hour balancing" or equalization ensures that wear and tear is distributed evenly across all units, streamlining maintenance schedules and extending the overall life of the equipment.

-

-

The "VSD Trim" Strategy: The Pinnacle of Efficiency:

-

This is where master controllers truly shine. The most effective control strategy for a system with mixed compressor types is "VSD Trim." The logic works as follows:

-

Base Load Management: The master controller uses the most efficient fixed-speed compressors to handle the stable, bulk portion of the plant's air demand (the "base load"). It runs these machines fully loaded, which is their most efficient operating point.

-

Trim Load Management: The controller designates a VSD compressor as the "trim" unit. This VSD runs at partial speed, precisely matching the fluctuating portion of the plant's demand. If demand increases slightly, the VSD speeds up. If it decreases slightly, the VSD slows down.

-

This strategy ensures the large fixed-speed machines aren't cycling wastefully, and the VSD is used exactly as intended—to handle variability. This combination is the gold standard for energy efficiency in multi-compressor systems.

-

-

Predictive Logic and Smart Controls (The 2025 Standard):

-

Today's advanced master controllers can do more than just react. They learn your facility's unique demand patterns. For example, the controller can learn that a large demand event always occurs at the start of a shift. It can then proactively start a base-load compressor just before the event, preventing a system pressure drop, rather than waiting for the pressure to fall and then reacting. Some can even be programmed with time-of-use electricity rates to prioritize running certain compressors during off-peak hours to minimize cost.

-

Benefits Beyond Energy Savings

While the ROI from energy savings is typically very high (often with a payback period of 1-3 years), master controllers offer other significant advantages:

-

Improved System Reliability: Stable system pressure reduces stress on downstream equipment and pneumatic tools.

-

Reduced Maintenance Costs: By preventing excessive cycling and balancing run hours, the controller minimizes wear and tear on motors, starters, and other compressor components.

-

Enhanced System Visibility: Provides a single HMI screen to view the status, pressure, and run hours of the entire compressor room, simplifying monitoring and diagnostics.

-

Future-Proof Scalability: When you add a new compressor during a plant expansion, it can be easily integrated into the master controller's logic.

Blackhawk Equipment: Your Partner in Advanced System Control

Implementing a master controller requires more than just plugging in a box. It demands a deep understanding of compressed air system dynamics. At Blackhawk Equipment, we are experts in this field. We help our clients by:

-

Conducting a thorough system audit to determine if a master controller is the right solution for your specific mix of compressors and demand profile.

-

Selecting the appropriate master controller that is compatible with all of your compressors, regardless of brand.

-

Professionally installing and commissioning the system, including the critical placement of the system pressure transducer and programming the controller with the correct equipment parameters.

-

Integrating the controller's output with your plant-wide SCADA or building automation systems for centralized visibility.

Conclusion: Stop Managing Machines, Start Orchestrating a System

If your facility operates multiple air compressors, it's time to stop thinking of them as individual machines and start treating them as a single, integrated system. A master controller provides the intelligent orchestration needed to eliminate waste, stabilize pressure, and unlock maximum energy efficiency. It ensures your most efficient compressors run when needed and prevents the costly chaos of uncoordinated control. Investing in a modern master controller is often one of the single most impactful energy-saving projects a facility can undertake.

Contact Blackhawk Equipment today for a system evaluation. Let us show you how the power of advanced sequencing logic can transform your compressor room from a major energy expense into a highly optimized and efficient utility.