Remote Monitoring and Control: Optimizing Industrial Utility Systems from Anywhere

03/18/2025

The industrial landscape is rapidly evolving, driven by advancements in connectivity and automation. Remote monitoring and control, powered by the Industrial Internet of Things (IIoT), is transforming how companies manage their critical infrastructure, including industrial utility systems. The ability to access real-time data, analyze performance trends, and control equipment from anywhere in the world is unlocking unprecedented levels of efficiency, responsiveness, and cost savings. Blackhawk Equipment is at the forefront of this revolution, providing cutting-edge remote monitoring and control solutions that empower our customers to optimize their operations and gain a competitive edge.

The Power of Connectivity

The foundation of remote monitoring and control is the seamless connection between industrial equipment and a central platform, typically cloud-based. This connectivity is enabled by the IIoT, which leverages:

-

Sensors: Embedded in equipment (compressors, pumps, chillers, boilers, etc.), these sensors collect real-time data on various parameters, such as:

-

Pressure

-

Temperature

-

Flow Rate

-

Vibration

-

Electrical Current

-

Power Consumption

-

Oil Quality

-

-

Gateways: These devices act as intermediaries, collecting data from sensors and transmitting it to the cloud platform. They often handle protocol conversion and data buffering.

-

Cloud Platforms: These secure, scalable platforms provide the infrastructure for storing, processing, and analyzing the vast amounts of data generated by IIoT devices. They also provide the user interface for monitoring and control.

-

Edge Computing: Processing some data at the "edge" (closer to the equipment), before transmitting it to the cloud reduces latency.

Benefits of Remote Monitoring and Control

The advantages of implementing remote monitoring and control for industrial utility systems are substantial:

-

Improved Efficiency: Real-time data allows for continuous optimization of equipment settings. For example, compressor output can be adjusted to match fluctuating demand, minimizing energy waste.

-

Reduced Downtime: Remote monitoring enables early detection of potential problems, allowing for proactive maintenance before a failure occurs. This minimizes unplanned downtime and its associated costs.

-

Enhanced Maintenance: Access to historical performance data helps identify trends and patterns, enabling predictive maintenance and optimized maintenance schedules.

-

Cost Savings: Reduced energy consumption, lower maintenance expenses, and minimized downtime all contribute to significant cost savings.

-

Improved Safety: Remote monitoring can detect hazardous conditions, such as gas leaks or overheating equipment, allowing for prompt intervention and preventing accidents.

-

Increased Productivity: By automating routine tasks and providing real-time insights, remote monitoring and control frees up personnel to focus on higher-value activities.

-

Better Decision-Making: Data-driven insights empower engineers and managers to make informed decisions about equipment operation and maintenance.

-

Remote Troubleshooting: Technicians can often diagnose and even resolve issues remotely, reducing the need for on-site visits.

Key Features of Remote Monitoring Systems

Effective remote monitoring systems typically include the following features:

-

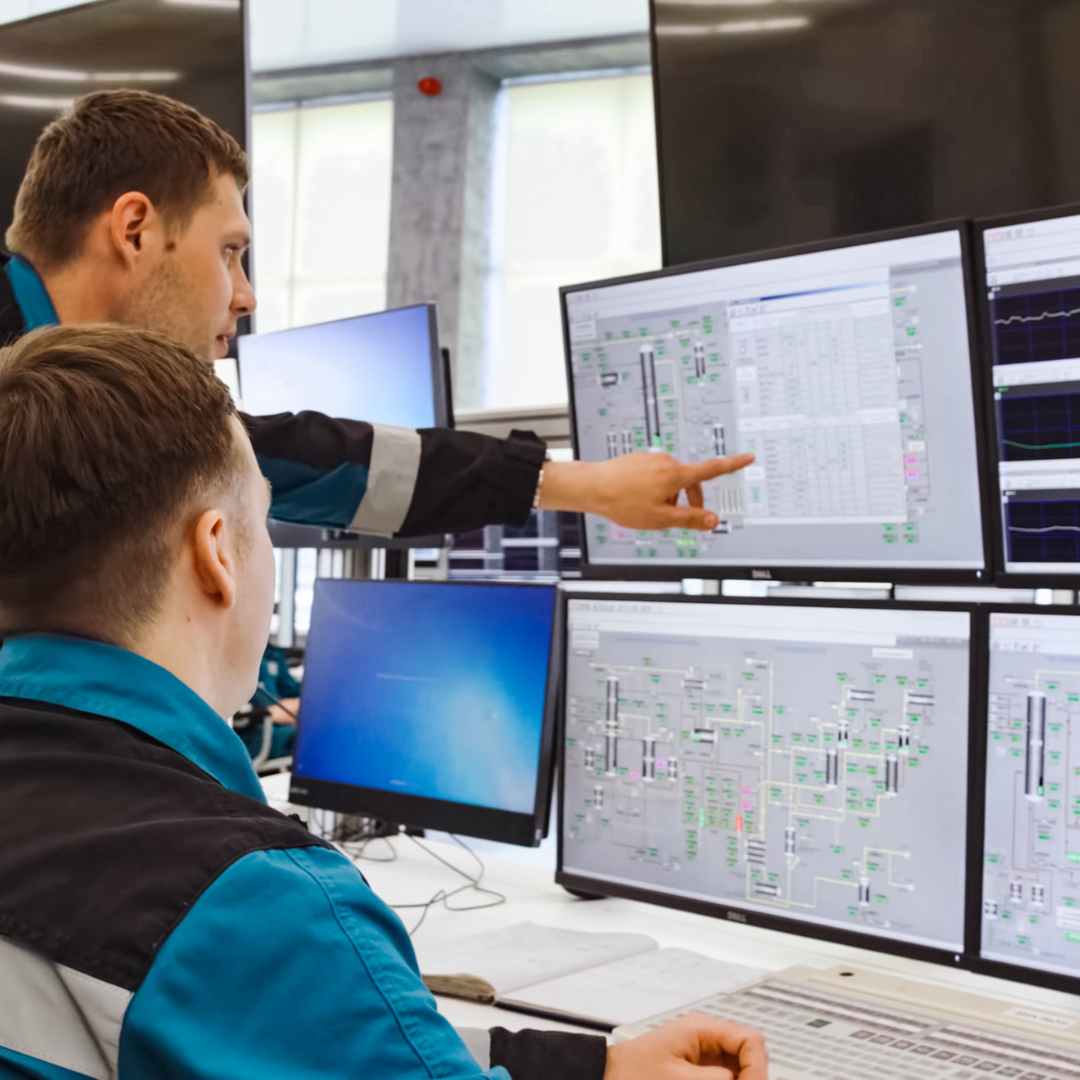

Real-time Data Visualization: User-friendly dashboards, charts, and graphs display real-time data from connected equipment, providing a clear overview of system performance.

-

Alerting and Notifications: The system automatically generates alerts (via email, SMS, or mobile app) when predefined thresholds are exceeded or anomalies are detected.

-

Remote Control Capabilities: Authorized users can remotely adjust equipment settings, start/stop equipment, and respond to alarms.

-

Data Logging and Reporting: The system stores historical data and generates reports for trend analysis, performance evaluation, and regulatory compliance.

-

User Access Control: Secure access control mechanisms ensure that only authorized personnel can access the system and control equipment.

-

Mobile Accessibility: Most systems offer mobile apps, so the information is at your fingertips.

Applications in Industrial Utility Systems

Remote monitoring and control can be applied to a wide range of industrial utility systems:

-

Compressed Air: Monitoring compressor performance (pressure, flow, power consumption, temperature), detecting leaks, optimizing control settings, and remotely starting/stopping compressors.

-

Pumping Systems: Monitoring pump status (on/off, flow rate, pressure, vibration), detecting cavitation or other problems, and remotely adjusting pump speed.

-

Cooling Systems: Monitoring chiller performance (temperature, flow, energy consumption), optimizing cooling tower operation, and detecting refrigerant leaks.

-

Hot Water Systems: Monitoring boiler efficiency, water temperature, and pressure, and remotely adjusting setpoints.

-

Steam Systems: Monitoring steam pressure, flow, trap functionality.

-

HVAC Systems: Monitor energy efficiency of the building.

Addressing Cybersecurity Concerns

With increased connectivity comes the need for robust cybersecurity. Protecting industrial control systems from cyberattacks is crucial. Best practices include:

-

Network Segmentation: Isolating industrial control systems from other networks to limit the impact of a potential breach.

-

Access Control: Implementing strong authentication and authorization mechanisms to restrict access to authorized personnel only.

-

Intrusion Detection Systems: Deploying systems that monitor network traffic for suspicious activity.

-

Regular Security Updates: Keeping software and firmware up-to-date to patch vulnerabilities.

-

Encryption: Encrypting data transmitted between devices and the cloud platform.

-

VPNs and Firewalls: Protecting network access with VPNs and appropriately configured firewalls.

Blackhawk Equipment's Remote Monitoring Solutions

Blackhawk Equipment is a leader in providing remote monitoring and control solutions for industrial utility systems. We partner with top technology providers, like VPInstruments, to offer comprehensive, customizable systems that meet the specific needs of our customers. Our solutions include:

-

Hardware: Sensors, gateways, and other necessary hardware for connecting equipment to the network.

-

Software: Cloud-based platforms for data visualization, analysis, alerting, and remote control.

-

Integration: Seamless integration with existing control systems and business applications.

-

Installation and Support: Expert installation, configuration, and ongoing support services.

Conclusion

Remote monitoring and control is transforming the management of industrial utility systems, empowering companies to achieve unprecedented levels of efficiency, reliability, and cost savings. By embracing this technology, businesses can optimize their operations, reduce their environmental impact, and gain a competitive advantage. Blackhawk Equipment is your trusted partner in implementing these cutting-edge solutions.

Contact Blackhawk Equipment today for a demonstration and discover how remote monitoring and control can revolutionize your operations. Let us help you unlock the full potential of your industrial utility systems with the power of connectivity and data-driven insights.