Beyond Basic Filtration: Achieving Optimal Air Purity with Sullair Air Treatment Filtration Systems

05/28/2025

In our previous discussion, we highlighted the critical role of Sullair air treatment dryers in removing detrimental moisture from compressed air systems. While dryers are essential for tackling bulk water and water vapor, achieving true air purity for many demanding industrial applications requires a further step: advanced filtration. Compressed air, even after drying, can still harbor a variety of other contaminants – solid particulates, oil aerosols, oil vapor, and even microorganisms – that can compromise sensitive processes, damage downstream equipment, and affect final product quality. Sullair, a leader in complete compressed air solutions, offers a comprehensive suite of air treatment filtration systems designed to go "beyond basic," meticulously targeting these diverse contaminants. As of May 2025, adhering to stringent air quality standards is more critical than ever, and Blackhawk Equipment is dedicated to helping you implement Sullair’s high-performance filtration solutions for ultimate system protection and process integrity.

The Hidden Threats: Understanding Contaminants Beyond Bulk Water

While a high-quality Sullair dryer effectively reduces the pressure dew point and removes condensed water, a range of other contaminants can persist or be introduced into the compressed air stream:

-

Solid Particulates:

- These include atmospheric dust drawn in by the compressor, rust particles and pipe scale dislodged from air receivers and piping, wear particles generated within the compressor itself, and even desiccant dust if a desiccant dryer is used. These particles, varying in size from coarse to sub-micron, can cause blockages in small orifices, score pneumatic cylinders, damage sensitive instruments, and contaminate products.

-

Oil Contamination (from lubricated compressors):

- Oil Aerosols: These are fine droplets of liquid oil, typically in the sub-micron range, that are carried over from the compressor's lubrication system. They can foul heat exchangers, contaminate desiccant beds in dryers, cause paint defects, and spoil products in food/beverage or pharmaceutical applications.

- Oil Vapor: This is oil in its gaseous state. Even after coalescing filters remove oil aerosols, oil vapor can remain. For applications demanding "technically oil-free" air, oil vapor removal is crucial.

-

Water Aerosols:

- Even with an efficient dryer, fine water aerosols can sometimes persist or re-condense if the air temperature drops significantly downstream. These can contribute to the same problems as bulk water, albeit on a smaller scale initially.

-

Microorganisms:

- In certain environments or if moisture is present, bacteria and mold can grow within compressed air systems, posing a significant risk in sterile applications like food processing, pharmaceuticals, and medical device manufacturing.

The specific contaminants and their concentration will vary depending on the compressor type, ambient air quality, system age, and maintenance practices. However, their potential for harm underscores the need for targeted filtration.

Sullair's Filtration Philosophy: A Multi-Stage Defense for Absolute Purity

Sullair recognizes that achieving optimal air purity, often defined by standards like ISO 8573-1 (which classifies compressed air quality based on particulate, water, and oil content), typically requires a systematic, multi-stage filtration approach. A single filter type is rarely sufficient to address the diverse range of contaminants. Sullair's filtration strategy involves deploying a series of filters, each engineered to efficiently remove specific types and sizes of contaminants, working synergistically to deliver air of the required quality.

Key Sullair Filtration Technologies and Their Specific Roles

Sullair offers a robust portfolio of filters, each designed with specific performance characteristics:

-

Sullair Particulate Filters (Dry Particulate / Dust Filters – e.g., SPF, SPX Series):

- Working Principle: These filters mechanically separate solid particles from the airstream using high-efficiency filter media, often made from pleated cellulose or advanced synthetic fibers.

- Target Contaminants: Primarily designed to remove solid contaminants such as atmospheric dust, rust, pipe scale, and wear particles. They are also crucial as after-filters for desiccant dryers to capture any desiccant dust.

- Efficiency & Ratings: Sullair particulate filters are rated based on their ability to remove particles down to a specific micron size (e.g., 1 micron for general protection, down to 0.01 micron for finer particulate removal).

- Features: Robust housing, low pressure drop design to minimize energy consumption, and differential pressure indicators to signal when element replacement is due.

-

Sullair Coalescing Filters (Oil & Water Aerosol Removal – e.g., SCH, SCX, SCO Series):

Working Principle: These are arguably the most critical filters for removing liquid contaminants. They utilize a deep bed of specialized borosilicate microfiber media. As air passes through, fine oil and water aerosols collide with the fibers and with each other, merging (coalescing) into larger droplets. These larger droplets are then gravitationally drained from the filter housing via an automatic drain.

Working Principle: These are arguably the most critical filters for removing liquid contaminants. They utilize a deep bed of specialized borosilicate microfiber media. As air passes through, fine oil and water aerosols collide with the fibers and with each other, merging (coalescing) into larger droplets. These larger droplets are then gravitationally drained from the filter housing via an automatic drain.- Design: Typically feature a multi-layer construction with an inner coalescing layer and an outer drainage layer to optimize separation and prevent re-entrainment of liquids.

- Efficiency & Performance: Sullair high-efficiency coalescing filters are designed to remove sub-micron oil and water aerosols (often down to 0.01 micron particle size) and can achieve very low residual oil content (e.g., 0.01 ppm or lower).

- Placement: Usually installed in series, with a general-purpose coalescing filter followed by a high-efficiency one for optimal oil removal.

-

Sullair Activated Carbon Filters (Oil Vapor & Odor Removal – e.g., SCV Series):

- Working Principle: These filters employ the principle of adsorption. The compressed air passes through a bed of highly porous activated carbon granules or cloth. The vast internal surface area of the activated carbon attracts and traps hydrocarbon (oil) vapors and associated odors.

- Placement: Critically, activated carbon filters must be placed after high-efficiency coalescing filters. This is because liquid oil will quickly saturate the activated carbon, rendering it ineffective. The coalescing filter removes the aerosols, allowing the carbon filter to focus solely on the vapor phase.

Result: Properly applied, Sullair activated carbon filters can deliver "technically oil-free" air, with residual oil vapor content often below 0.003 ppm, suitable for very sensitive applications.

Result: Properly applied, Sullair activated carbon filters can deliver "technically oil-free" air, with residual oil vapor content often below 0.003 ppm, suitable for very sensitive applications.- Maintenance: Activated carbon elements have a finite lifespan and must be replaced regularly as their adsorption capacity is exhausted.

Designing an Effective Sullair Filtration System: Best Practices

Implementing a successful filtration strategy requires careful planning:

- Define Air Quality Requirements: Identify the most stringent air quality needed for any point-of-use application in your facility, often referencing ISO 8573-1 classes for solid particulate, water, and total oil.

- Correct Sizing: Filters must be sized based on the maximum air flow rate (CFM or m³/hr) and operating pressure of your system. Undersized filters lead to high pressure drop (wasting energy) and reduced filter life. Oversizing can sometimes be inefficient.

- Proper Sequencing: The order of filters is paramount for both effectiveness and protecting downstream elements. A typical sequence might be: General Purpose Particulate Filter -> High-Efficiency Coalescing Filter -> Activated Carbon Filter (if oil vapor removal is needed) -> Sterile Filter (if applicable).

- Installation and Maintenance: Ensure filters are installed correctly to prevent bypass. Monitor differential pressure across each filter regularly; a high differential pressure indicates a clogged element that needs replacement. Timely element replacement is crucial for maintaining air quality and minimizing energy waste. Using genuine Sullair replacement elements ensures rated performance.

The Indispensable Partnership: How Sullair Filters and Dryers Work in Tandem

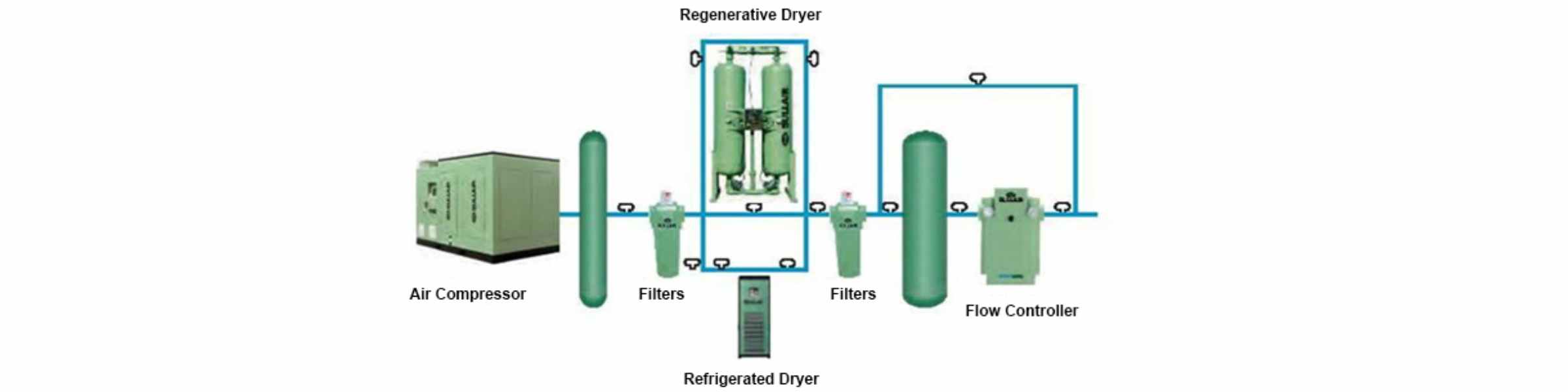

It's crucial to understand that Sullair dryers and Sullair filters are not mutually exclusive; they are complementary components of a comprehensive air treatment system.

- Dryers Protect Filters: By removing bulk water and significantly reducing water vapor, Sullair dryers prevent liquid water from overwhelming coalescing filters and protect activated carbon beds from moisture, extending their life and efficiency.

- Filters Protect Dryers and Refine Air Quality: Coalescing pre-filters protect the sensitive heat exchangers in refrigerated dryers and the desiccant beds in adsorption dryers from oil contamination. Downstream filters remove contaminants that dryers do not target (like particulates, oil aerosols/vapor, and desiccant fines). This integrated "Sullair Total Air System" approach ensures that each component operates optimally, delivering consistently high-quality compressed air.

Blackhawk Equipment: Your Expert Guide to Sullair Filtration Solutions

Selecting and configuring the right Sullair filtration train for your specific needs requires in-depth knowledge. Blackhawk Equipment's team offers:

- Air Quality Assessment: Helping you determine the precise air purity requirements for your applications.

- System Design Expertise: Recommending the optimal combination and sequence of Sullair filters, correctly sized for your system.

- Genuine Sullair Products: Supplying genuine Sullair filters and replacement elements to guarantee performance and reliability.

- Comprehensive Service: Providing installation, maintenance, and troubleshooting support for your entire Sullair air treatment system.

Conclusion: Achieving Ultimate Air Purity with Sullair's Advanced Filtration

For today’s demanding industrial processes, simply removing bulk moisture from compressed air is often not enough. Achieving optimal air purity—free from detrimental solid particulates, oil aerosols, and oil vapor—is essential for protecting sensitive equipment, ensuring final product quality, and maximizing operational efficiency. Sullair’s comprehensive range of air treatment filtration systems provides targeted, high-performance solutions to meet the most stringent air quality standards. By understanding the nature of contaminants and implementing a correctly designed, multi-stage Sullair filtration system, you can safeguard your operations and ensure the integrity of your processes.

Don’t let contaminants compromise your compressed air system. Contact Blackhawk Equipment today to explore Sullair's advanced filtration technologies and let our experts design a solution that delivers the precise air quality your facility demands.