A Practical Guide to Vibration Analysis for Predictive Maintenance in Pumps and Compressors

08/11/2025

A Practical Guide to Vibration Analysis for Predictive Maintenance in Pumps and Compressors

All rotating machinery vibrates. A brand new, perfectly balanced pump or compressor has a natural, low-level vibration signature—a sign that it's healthy and operating as designed. Over time, however, as components wear, loads change, and minor issues develop, this signature begins to change. These subtle changes, often undetectable by human senses, are the earliest warnings of impending failure. Vibration analysis is the cornerstone of modern Predictive Maintenance (PdM) programs because it allows us to capture and interpret these changes, transforming maintenance from a reactive, fire-fighting exercise into a proactive, data-driven science. At Blackhawk Equipment, we leverage advanced diagnostics like vibration analysis to ensure the long-term reliability of the critical systems we support.

What is Vibration Analysis?

In simple terms, vibration analysis is the process of measuring the vibration signals from a machine, analyzing the data, and using that information to determine the machine's health and identify specific developing faults. Think of it like a doctor using an EKG to analyze a patient's heart. A doctor sees more than just a heartbeat; they see the rate, the rhythm, and the electrical signature, which can reveal underlying conditions. Similarly, a trained vibration analyst can "listen" to a machine's vibration signature and diagnose specific mechanical problems—like bearing wear or shaft misalignment—long before they become catastrophic

that information to determine the machine's health and identify specific developing faults. Think of it like a doctor using an EKG to analyze a patient's heart. A doctor sees more than just a heartbeat; they see the rate, the rhythm, and the electrical signature, which can reveal underlying conditions. Similarly, a trained vibration analyst can "listen" to a machine's vibration signature and diagnose specific mechanical problems—like bearing wear or shaft misalignment—long before they become catastrophic

Key Measurements in Vibration Analysis:

The analysis looks at several key aspects of the vibration signal:

-

Amplitude: This measures the intensity of the vibration (how much it's moving). A rising amplitude is a clear sign that a problem is getting worse.

-

Frequency: This measures how often the machine is vibrating (cycles per second or minute). Frequency is the key to diagnostics, as different problems generate vibrations at specific, predictable frequencies.

-

Direction: The analysis also considers the direction of the vibration (e.g., horizontal, vertical, axial—along the shaft), which provides further clues to the root cause.

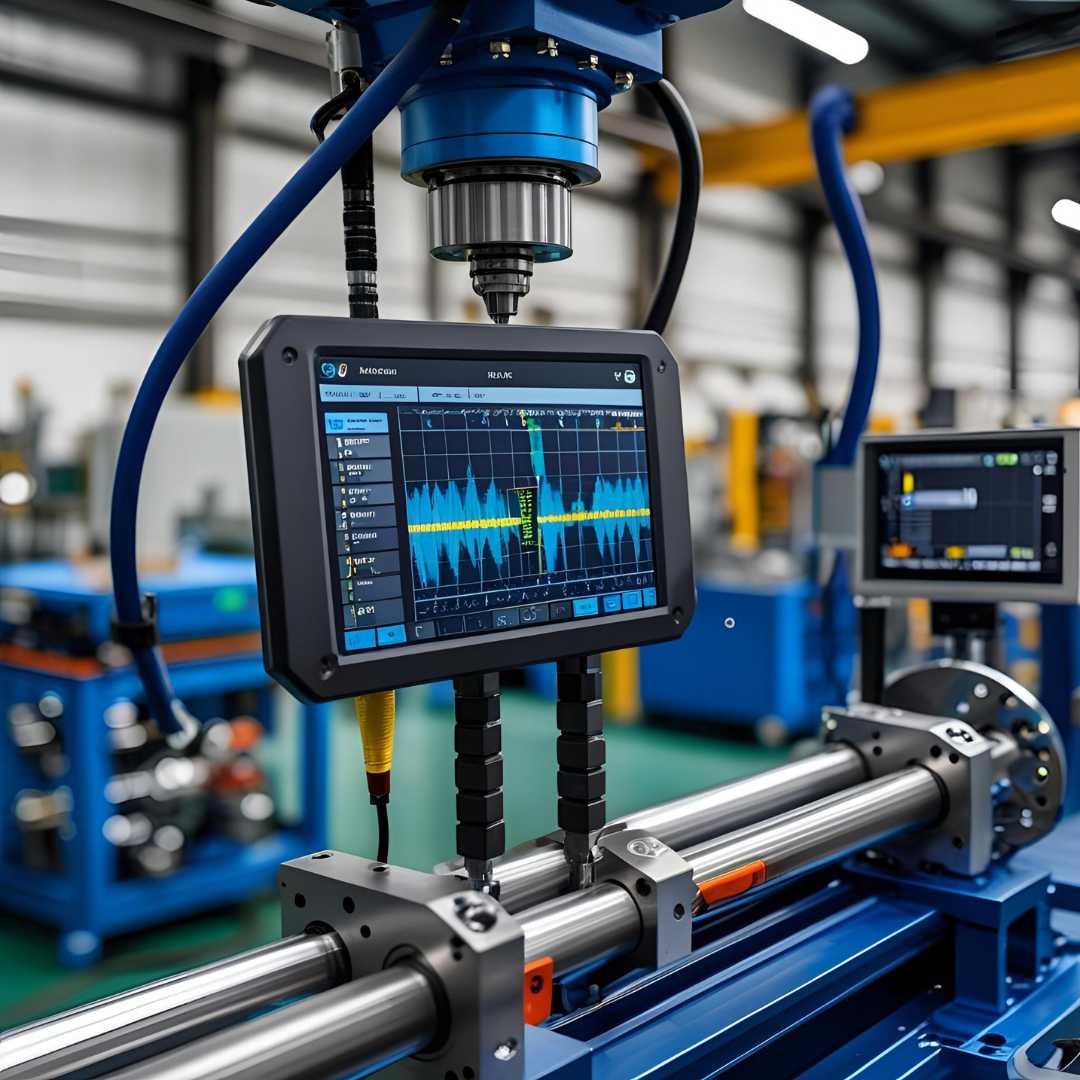

The Tools of the Trade: How Vibration Data is Collected

-

Portable Data Collectors:

-

The traditional method involves a maintenance technician using a handheld data collector with a sensor (typically an accelerometer) to take periodic readings at predefined, labeled points on a machine. This data is then uploaded to a computer for analysis. This is a powerful method for detailed analysis but is labor-intensive and only provides a snapshot in time.

-

-

The Rise of Wireless Continuous Monitoring (The 2025 Standard):

-

A major advancement in recent years is the availability of cost-effective, battery-powered wireless vibration sensors. These sensors can be easily and permanently installed on critical equipment like pumps and compressors. They continuously monitor vibration and temperature, transmitting data wirelessly to a central gateway and onto a cloud platform or local server. This approach provides 24/7 monitoring, captures transient events that periodic checks might miss, and makes it feasible to monitor a much wider range of assets.

-

What Vibration Analysis Can Detect: A Diagnostic Cheat Sheet for Engineers

This is where the true power of vibration analysis lies. By analyzing the frequencies present in the vibration signal (often through a process called Fast Fourier Transform or FFT), an analyst can pinpoint the exact root cause of a problem.

-

Imbalance:

-

Symptom: A "heavy spot" on a rotating component like a fan, impeller, or motor rotor.

-

Vibration Signature: A strong vibration peak that occurs at a frequency equal to 1x the running speed of the component. For example, a motor running at 1800 RPM will show a dominant vibration peak at 1800 cycles per minute (CPM) or 30 Hertz (Hz).

-

-

Misalignment:

-

Symptom: When the shafts of two coupled machines, like a motor and a pump, are not perfectly aligned. This is one of the most common causes of premature failure.

-

Vibration Signature: Misalignment typically creates a strong vibration peak at 2x the running speed. Significant vibration in the axial direction (along the shaft) is also a classic indicator of misalignment.

-

-

Mechanical Looseness:

-

Symptom: Worn or loose mounting bolts, cracks in the machine frame or foundation, or excessive clearance in bearings.

-

Vibration Signature: Looseness often creates a series of vibration peaks at multiple harmonics (whole number multiples) of the running speed, such as 1x, 2x, 3x, and so on.

-

-

Bearing Failures: The Ultimate Early Warning System:

-

This is where vibration analysis provides its greatest return on investment. A bearing in the early stages of failure generates very high-frequency, low-amplitude signals as microscopic faults appear on the races or rolling elements.

-

These signals are completely undetectable by ear and often don't even generate enough heat to be caught by temperature monitoring. Vibration analysis, using specific techniques like spectral enveloping, can detect these faults months in advance of a catastrophic failure. This allows you to plan a scheduled replacement during a planned outage, rather than dealing with a costly and unexpected seizure.

-

-

Pump and Blower Specific Issues:

-

Vibration analysis can also detect issues like pump cavitation (which creates random, high-frequency vibration), flow turbulence, and damage to impeller vanes or blower rotors, each of which has its own unique vibrational signature.

-

Implementing a Vibration Analysis Program: A Practical 5-Step Approach

-

Step 1: Identify and Prioritize Critical Assets: You don't need to monitor every machine in your plant. Start with the most critical equipment—your main air compressors, key process pumps, and essential cooling system components—where an unexpected failure would cause the most significant production loss.

-

Step 2: Establish a Baseline: When a machine is new or has just been rebuilt and is known to be in good condition, take a detailed vibration reading. This becomes the "fingerprint" or baseline signature of a healthy machine.

-

Step 3: Define a Measurement Schedule and Alarms: For periodic checks, establish a consistent schedule (e.g., monthly). For continuous wireless systems, set alarm thresholds—a "Warning" level for investigation and a "Critical" level for immediate action.

-

Step 4: Trend the Data Over Time: The real power of vibration analysis is in trending. A single reading tells you the condition today; a trend line tells you where the condition is heading. A steady upward trend in a specific vibration amplitude is a clear signal that a fault is progressing.

-

Step 5: Analyze, Diagnose, and Act: When an alarm is triggered or a negative trend is identified, this is when detailed analysis is required. This step often requires a certified vibration analyst to interpret the complex spectral data, pinpoint the root cause, and provide a clear, actionable maintenance recommendation.

Blackhawk Equipment: Leveraging Vibration Analysis for Your Reliability

At Blackhawk Equipment, we understand that selling a high-quality pump or compressor is just the beginning. Ensuring its long-term reliability is paramount. We leverage vibration analysis as a key tool to support our customers by:

-

Providing Diagnostic and Troubleshooting Services: When you have a "problem machine" with recurring failures, our technicians can use vibration analysis as a non-intrusive tool to find the true root cause.

-

Incorporating Vibration Analysis into Maintenance Agreements: As part of our comprehensive service and Preventive Maintenance programs, we can incorporate periodic vibration readings for your critical utility equipment, helping you move towards a truly predictive strategy.

-

Verifying Installation and Commissioning: We can take baseline readings on newly installed equipment to verify a quality installation and provide a starting point for the asset's lifecycle monitoring.

-

Providing Expert Analysis: We have the expertise to interpret the vibration data and translate it into clear, actionable maintenance recommendations—like "Schedule an alignment check on Pump-101" or "Plan to replace the motor outboard bearing on Compressor-3 within the next three months."

Conclusion: Listening to Your Machinery Before It Shouts

Vibration analysis effectively allows you to listen to the health of your machinery long before it starts to "shout" through loud noises, overheating, or catastrophic failure. It transforms maintenance from a reactive or guess-based activity into a proactive, data-driven science. By detecting specific faults like imbalance, misalignment, and especially bearing wear months in advance, you can plan repairs, reduce downtime, and significantly extend the life of your critical pumps and compressors. Implementing a vibration analysis program is one of the most effective investments you can make in your plant's overall reliability.

Contact Blackhawk Equipment today to discuss how we can help you integrate vibration analysis into your maintenance strategy. Let us help you achieve new levels of operational reliability by understanding what your equipment is trying to tell you.