What Is Compressor Varnish and How Do You Stop It?

07/19/2025

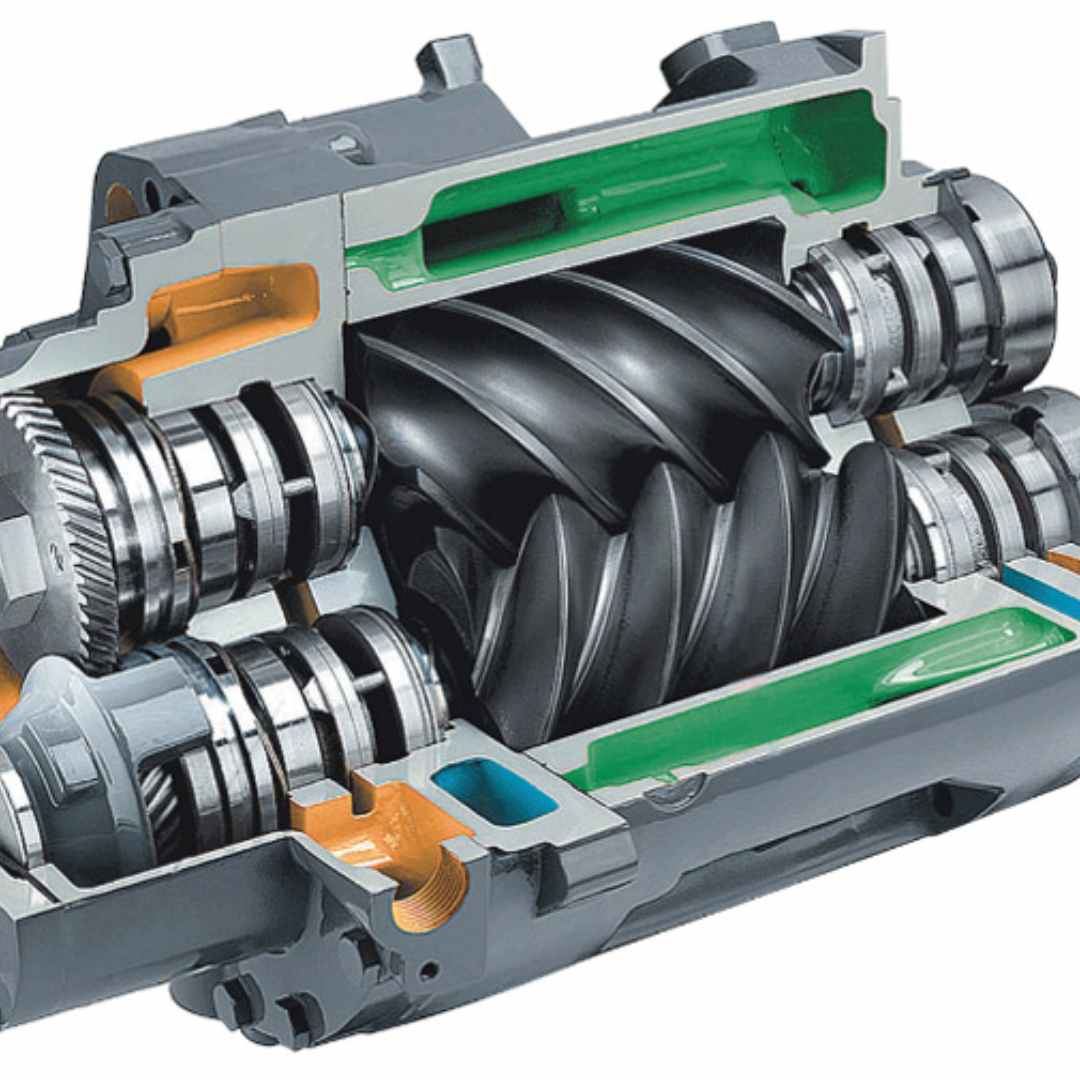

As an engineer or maintenance professional, you may have heard the term "varnish" in relation to your rotary screw air compressors. It’s often blamed for overheating issues, high energy consumption, and even premature equipment failure. But what exactly is it? It's far more sinister than just "dirty oil." Varnish is a persistent, insulating deposit that silently strangles the performance and reliability of your most critical assets. Understanding this common but costly problem is the first step toward defeating it. At Blackhawk Equipment, our service technicians regularly confront the damage caused by varnish. This guide will answer two fundamental questions: What is compressor varnish, and what are the effective, practical strategies you can implement to stop it for good?

Part 1: What Exactly Is Compressor Varnish?

Compressor varnish is a hard, sticky, lacquer-like substance that plates onto the internal surfaces of a compressor. Unlike "sludge," which is typically soft and composed of oil, water, and solid contaminants, varnish is the result of a chemical reaction. It bonds tightly to metal surfaces, acting as a powerful insulator and restricting flow through critical pathways.

-

The Chemistry of Varnish Formation: A Story of Oxidation:

-

At its core, varnish is a byproduct of lubricant degradation, primarily caused by oxidation. The intense heat and pressure inside the compression chamber, combined with exposure to oxygen from the air, causes the oil's long hydrocarbon molecules to break down.

-

As these molecules shear and oxidize, they become unstable and begin to polymerize—linking together to form larger, insoluble compounds. These compounds are no longer carried in suspension by the lubricant. They begin to drop out and adhere to surfaces, especially hot metal surfaces, where they "bake on" to form the familiar hard, sticky varnish deposit.

-

-

Where Varnish Forms and Why It's So Destructive:

-

Varnish doesn't form uniformly; it targets specific areas, which is what makes it so destructive. It precipitates in areas of high temperature and low fluid flow. Key problem locations include:

-

Oil Coolers: Varnish coats the inside of cooler tubes and fins, acting as an insulator. This drastically reduces the cooler's ability to dissipate heat, causing the compressor's operating temperature to rise and creating a vicious cycle where more heat leads to more varnish.

-

Oil Separator Elements: Varnish can clog the fine fibers of the separator element. This increases the pressure drop across the separator, leading to higher energy consumption and eventually causing oil carryover into your plant's air system.

-

Bearings and Internal Passages: Deposits can restrict oil flow to critical bearings, leading to insufficient lubrication and premature failure of the air end—the most expensive component of your compressor.

-

Thermostatic Valve: This critical valve, which regulates oil flow to the cooler, can become sticky or clogged by varnish, leading to severe temperature control problems.

-

-

-

The Primary Causes of Varnish Formation:

-

High Operating Temperature: This is the number one accelerator of oil oxidation and varnish formation. For every 18°F (10°C) increase in temperature above a lubricant's normal operating range, the rate of oxidation roughly doubles. Poor ventilation, dirty coolers, and high ambient temperatures (especially in summer) are major culprits.

-

Using the Wrong Lubricant: Using a lower-quality mineral oil in a demanding, hot-running industrial application is a direct path to varnish problems. Mineral oils lack the thermal stability to resist breakdown under these conditions.

-

Contamination: Mixing incompatible lubricants (e.g., adding a PAO synthetic to a PAG-based oil) can cause an adverse chemical reaction and rapid lubricant breakdown. Contamination with water or process chemicals can also accelerate degradation.

-

Improperly Extended Drain Intervals: Attempting to run a lubricant, especially a mineral-based one, far beyond its recommended service life guarantees that it will break down and form deposits.

-

Part 2: How Do You Stop It? A Proactive, Two-Pronged Approach

The most effective strategy for dealing with varnish involves two key components: prevention for clean systems and removal for systems already affected.

Prevention: The Best and Most Cost-Effective Strategy

-

Control Your Operating Temperature:

-

Since heat is the primary catalyst, temperature control is your first line of defense. Ensure your compressor room has adequate ventilation to remove radiated heat. Regularly and thoroughly clean your compressor's oil cooler and aftercooler to ensure maximum heat transfer. If your system is water-cooled, verify that the cooling system is clean and providing adequate flow.

-

-

Select the Right Lubricant (The Most Critical Step):

-

This is the single most important decision you can make to prevent varnish. Modern synthetic lubricants are engineered at a molecular level for superior thermal and oxidative stability. High-quality synthetics, like those based on Polyalphaolefins (PAOs), are designed to resist breakdown at high temperatures. While their initial purchase price is higher, they are the best insurance policy against the costly damage and downtime caused by varnish.

-

-

Adhere to Proper Maintenance Schedules:

-

Follow the OEM-recommended drain intervals for the specific lubricant you are using. Don't guess. Using genuine, high-quality oil filters and separator elements is also critical, as proper filtration removes contaminants that can act as catalysts for oil degradation.

-

-

4. Implement a Proactive Oil Analysis Program:

-

Regular oil analysis is like a blood test for your compressor. It provides a snapshot of the lubricant's health and can predict varnish potential long before it becomes a major problem. Key tests include monitoring the Acid Number (AN) and viscosity for signs of breakdown. Advanced tests like Membrane Patch Colorimetry (MPC) can specifically measure the oil’s varnish potential.

-

Removal: Strategies for Addressing Existing Varnish Problems

If you've inherited a system with a history of running hot or suspect varnish is already present, you have several options for removal.

-

System Flushes and Cleaning Agents:

-

This is a common first step for systems with moderate varnish. A specialized system cleaning fluid or flush concentrate is added to the old oil and circulated for a specific period (e.g., 24-48 hours) while the compressor runs. These agents are designed to dissolve existing varnish deposits back into the oil. The system is then completely drained while still warm, flushed if necessary, and refilled with new, high-quality synthetic oil and new filters. This process must be performed carefully to avoid dislodging too much debris at once and clogging the system.

-

-

Off-Line Varnish Removal Systems:

-

For more persistent problems, an external, "kidney-loop" filtration system can be connected to the compressor. This unit continuously circulates the compressor's oil through specialized filtration media (like electrostatic or depth media filters) that are designed to remove not just solid particles, but also the soluble varnish precursors from the oil while the compressor is operating.

-

-

Manual Cleaning:

-

In severe cases, a complete teardown and manual or chemical cleaning of individual components like the oil cooler, separator tank, and even the air end may be required. This is an extremely labor-intensive and expensive process, which highlights why prevention is always the better strategy.

-

Blackhawk Equipment: Your Partner in Varnish Prevention and Remediation

Dealing with compressor varnish requires expertise. The team at Blackhawk Equipment can help you:

-

Perform expert diagnostics to determine if varnish is the root cause of your compressor's performance issues.

-

Recommend and supply the correct, OEM-approved high-performance synthetic lubricant for your specific application.

-

Provide professional system flushing services to safely and effectively remove existing varnish.

-

Incorporate oil analysis into a comprehensive Preventive Maintenance program to monitor your lubricant’s health and prevent future problems.

Conclusion: A Clean Compressor is a Reliable and Efficient Compressor

So, what is compressor varnish? It's a performance-robbing deposit caused by oil oxidation, primarily driven by heat. How do you stop it? Through a proactive strategy focused on controlling operating temperatures, using the right high-quality synthetic lubricant, and monitoring the oil's health through regular analysis. While removal methods exist, preventing varnish from forming in the first place is always the most effective and economical approach. Protecting your compressor from varnish is a direct investment in your facility's operational reliability and energy efficiency.

If you suspect your compressor is suffering from the effects of varnish, or if you want to implement a proactive strategy to prevent it, contact Blackhawk Equipment today. Let our experts help you ensure the lifeblood of your compressor stays clean, cool, and effective.