INNOVATIVE COMPRESSED AIR

& EQUIPMENT SOLUTIONS

Extraction Industry ‒ Air Compressors

The extraction of cannabis and derivatives is now processed for a wide range of medical uses and consumer products ranging from food edibles and essential oils to beverages and lotions. Blackhawk Equipment has partnered with several major manufacturers of extraction equipment used in all three of the main extraction methods including supercritical CO2, ethanol, and liquid butane/propane to devise the ideal combination of industrial support equipment needed to operate extraction machines.

Blackhawk Equipment provides ancillary extraction equipment including air compressors, vacuum pumps, refrigerated/heating circulators, and chillers for cannabis extraction.

Why Blackhawk

- Industrial equipment distributor – equipment is suited for long term operation in harsh environments

- Offer centralized systems – air, vacuum, and chillers suited for larger scale and expandable operations

- Sizing and installation support – based on a proven track record in the industrial equipment market

- On hand inventory – replacement units and parts Service support – on all equipment represented

- Direct warranty coverage – as the factory direct manufacturer distributor

COMPRESSOR FEATURES:

- Highly efficient with low energy consumption

- Reliability – built for 24/7 operation

- Long life bearings

- Durability – legendary compressor performance with 5 and 10 year warranties Sounds enclosure reduces sound levels

- Easy maintenance

- Simple controller

AIR COMPRESSORS FOR BHO CANNABIS EXTRACTION 101

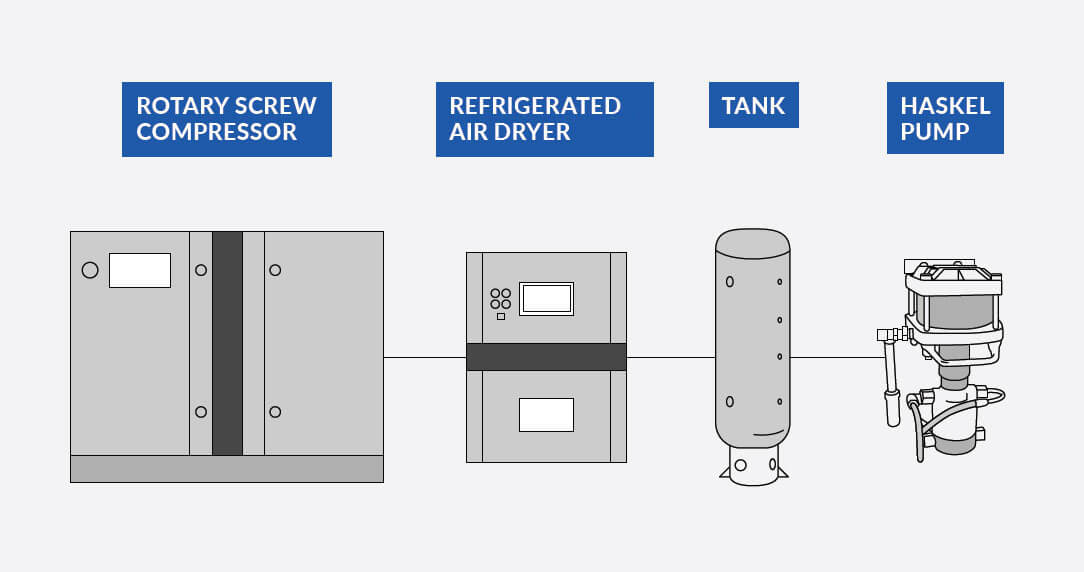

Customers who have a need to run the Haskel Recovery pump for extraction are frequently faced with the task of selecting, installing and operating a compressed air system for the first time. Frequent questions that come up are the following:

What Kind of Compressor Do I Need?

The difference between a reciprocating compressor and rotary screw compressors is expansive, but the simple answer is that a typical reciprocating compressor you may see at the hardware store is designed for intermittent use and if they are run in constant duty, the pump will quickly wear out. In contrast, a rotary screw compressor is designed for constant duty and operates best in constant duty. A Rotary Screw is ideally suited for a Haskel assisted recovery.

What Size Compressor Do I Need?

The Haskel requires 24-30 SCFM to run. Compressors are rated in ACFM, and get de-rated by about 20% in extreme elevations such as Denver, Colorado. A 10HP compressor may be capable of producing 36 SCFM at sea level or 28 SCFM in Denver. We have found that this can easily run a single Haskel. While a 15HP compressor can run two Haskel pumps at sea level, we typically recommend 20hp to be safe.

Does an Air Compressor Require Maintenance?

Like all rotating mechanical equipment, an air compressor does require maintenance. Compressors require service every 2,000 hours of operation. Maintenance is relatively simple and can be completed by a competent mechanic.

Where Should I Install the Air Compressor?

Many considerations should be made during install and consulting with your compressed air provider is very important.

Key considerations are:

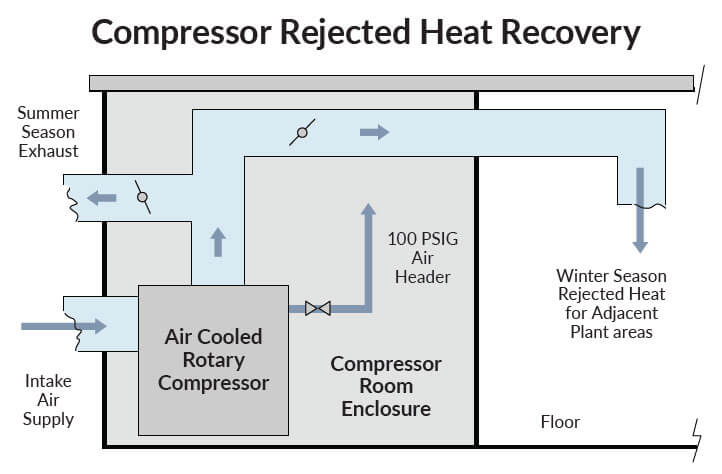

Heat Load – A 10hp compressor will produce almost 30,000 BTU/hr in the form of hot air blown off the top of the compressor. The most effective way to deal with this heat load is to directly duct the air out of the building.

Sound – A 10HP compressor is very quiet at 69dBA, so it is acceptable for indoor applications.

Environment – In areas that experience freezing temps, the compressed air system should be installed indoors, however if indoor space is impossible, outdoor installations are possible with outdoor buildings. Before any outdoor building is built for a compressor, you should talk with your air compressor provider.

What About Pipe?

The three most common types of compressed air piping are:

The three most common types of compressed air piping are:

Aluminum – The Infinity aluminum pipe system is extremely easy to install with little skill and modifications are simple. Aluminum is also very clean, does not corrode and is lightweight. Aluminum is recommended.

Black Iron – Material is cheap, but it is very difficult to install. The inside of the pipe can corrode and pass rust and debris downstream. Modifications after the fact can be extremely difficult.

Copper – Does not corrode, is a lightweight material and readily available. Installing copper requires a high level of skill and material can be very expensive.

What Power Is Required?

Ideally 3 phase 230V/208V for any compressor, however the single phase is available at the same price. Tech data sheets should always be provided to your electrician so that proper wire and breaker sizing is provided.

INNOVATIVE COMPRESSED AIR

& EQUIPMENT SOLUTIONS

Extraction Industry ‒ Chillers

The extraction of cannabis and derivatives is now processed for a wide range of medical uses and consumer products ranging from food edibles and essential oils to beverages and lotions. Blackhawk Equipment has partnered with several major manufacturers of extraction equipment used in all three of the main extraction methods including supercritical CO2, ethanol, and liquid butane /propane to devise the ideal combination of industrial support equipment needed to operate extraction machines.

Blackhawk Equipment provides ancillary extraction equipment including air compressors, vacuum pumps, refrigerated/heating circulators, and chillers for cannabis extraction.

Blackhawk Sells & Installs Air Chillers

Solid reputation inside extraction industry – we know the business and can recommend the best solutions

Experienced sales team – get inside knowledge and recommnedations

Multiple product options – get the solution that you need now and plan for the future

Quick ordering and delivery – Blackhawk makes the process easy

Direct warranty coverage – as the factory direct manufacturer distributor

UTILITY PROVIDER FOR EXTRACTION SERVICES

What is the difference between industrial grade and lab grade?

Lab Grade

Reduced capacity for small batches, designed for intermittent use in clean environments. May have features not needed like extremely tight temperature control.

Industrial Grade

Endless options for size, designed for 24/7 use in harsh environments included very hot or cold ambient. Supported by service based company experience in industrial environments.

Blackhawk Equipment, a service based company with experience

Air chillers deliver industrial air cooling in a small package.

Rotary & Scroll Style Copeland Compressors, Readily Available

Simple, efficient and used in hundreds of operations.

High Efficiency Evaporator in Tank

Coiled Heat Exchanger installed in the water/glycol tanks ensuring reduced ambient heat gain and steady temperature.

Designed for Extreme Ambient Conditions

Can operate in ambient conditions as low as -20F and high as 115F. *Higher ambient packages available. Can be configured to meet extreme temperature environments.

Controller Connectivity

Up to five units can be connected to maximizes redundancy and energy efficiency.

UL Listed

UL 508A Control Panel

Expansion Tank

Open or enclosed

Steel Construction

Frame and case is made from steel offering strength and reliability for ongoing use.

Stainless Steel Centrifugal Pumps

Water/glycol is pumped using a simple and reliable centrifugal pump that is designed for easy replacement.

CANNA COOL

CANNA COOL is a 40% Inhibited Propylene Glycol product used for Industrial Heat Transfer Fluid and is designed specifically for use in Cannabis Chilled Water Systems. Canna Cool is pre-blended with glycol and deionized water to prevent any sludge or reaction with make-up water hardness.

Why Use Canna Cool in your extraction process equipment?

Canna Cool is pre-mixed at 40% glycol and it has the proper amount of buffering agent (corrosion inhibitor) inside making it easy to use with your extraction equipment. Nothing to measure or formulate and if you keep a couple extra pails on hand you will always have what you need. No mixing or guessing, all you need to do is top off your system to keep your equipment running perfectly and your products safe from foreign residues and metals.

Isn’t city tap water OK to use?

Using city “tap” water can be acceptable for use as long as your city’s make-up water contains less than 70-100 ppm of total hardness. However, most Inhibited Propylene Glycol solutions use a phosphate based corrosion inhibitor (Dow, Texaco, Interstate, etc.) So when this phosphate interacts with your city’s water hardness it forms a precipitate that falls out in the form of a sludge and can cause plugging of orifices, heat exchangers and piping. So in NOT knowing where all this glycol is going, and not knowing the exact seasonal make-up qualities of your city water, it is safer to use a pure water source like Canna Cool.

Why can’t you just use de-ionized water?

De-Ionized (DI) water is water that has been run through a resin bed, alternating between cationic and anionic beds to rid the water of most impurities. This highly pure water is void of almost all substances so when it is introduced into a chilled water piping system for extraction, the fluid goes looking for something to balance the water, namely the iron, copper or stainless steel pipe. Using only this water would be a detriment to the piping and can introduce these pipe metals into your product. That is why in labs and other processes that use DI water it is run in non-ferrous piping. Canna Cool is already pre-mixed with glycol and phosphate corrosion inhibitors, which are a buffering agent. Canna Cool neutralizes the harmful make-up water byproducts in the extraction system.

What about using reverse osmosis water?

RO Water (Reverse Osmosis) is water that has been run through a membrane filtration. It is slightly lower in quality of de-ionized water and takes longer to produce. RO has all the same pitfalls of the DI water, but with Canna Cool added, it would be acceptable to use.

Recommendations

Our recommendation is to hit that “easy button” and use Canna Cool for your cannabis extraction equipment and chilled water system. With Canna Cool in your system you have no fear of plugging or fouling any equipment up as the Canna Cool will protect your metal systems. Without any leaks or repairs, the fluid should remain stable for 4-5 years as long as bacteria does not get into the system. Canna Cool has freeze protection down to -8º F and a burst temperature down to -40º F, which is great protection for unforeseen events and cold weather environments.