The Future of Industrial Utilities: How Smart Technologies are Paving the Way

01/29/2024

Industry 4.0, often referred to as the Fourth Industrial Revolution, is fundamentally changing the landscape of manufacturing and industrial operations. A major part of this transformation is the increasing adoption of smart technologies in the management and optimization of industrial utilities. From compressed air and fluid pumping to cooling systems, the integration of intelligent sensors, data analytics, and automation is ushering in a new era of efficiency, reliability, and proactive maintenance. Blackhawk Equipment is at the forefront of this revolution, helping companies embrace these advancements to unlock the full potential of their operations. This blog post explores how smart technologies are transforming industrial utilities and the benefits for engineers and their organizations.

Understanding Industry 4.0 and the Industrial Internet of Things (IIoT)

Industry 4.0 is characterized by the convergence of digital and physical technologies, creating interconnected systems that can communicate, analyze data, and make intelligent decisions. The Industrial Internet of Things (IIoT) is a key enabler of this revolution. IIoT involves connecting machines, devices, and systems to a network, allowing for the seamless collection and exchange of data. This connectivity, powered by technologies like sensors, cloud computing, edge computing, and machine learning, lays the foundation for smarter, more efficient industrial operations.

The Transformation of Industrial Utilities: From Reactive to Proactive

Traditionally, the management of industrial utilities like compressed air, pumping, and cooling has often been reactive, with maintenance and optimization efforts triggered by equipment failures or noticeable inefficiencies. Industry 4.0 is shifting this paradigm to a proactive, data-driven approach.

-

Compressed Air: Smart sensors, such as those offered by VPInstruments, can monitor air flow, pressure, leaks, and compressor performance in real-time. This data, when analyzed, provides valuable insights into system health, enabling predictive maintenance, optimized compressor control, and significant energy savings. Imagine being able to detect a leak as soon as it occurs, preventing wasted energy and costly downtime.

-

Fluid Pumping: IIoT sensors can be deployed to monitor pump performance metrics like flow rates, vibration, and energy consumption. This real-time data allows for early detection of anomalies, indicating potential issues like cavitation or bearing wear. Data analysis helps optimize pump operation, reduce energy consumption, and prevent catastrophic failures.

-

Cooling Systems: Smart sensors and controls can be integrated into cooling systems to monitor water temperature, flow rates, and chiller performance. This enables dynamic optimization of chiller operation based on real-time demand, resulting in significant energy savings and improved system stability.

Key Technologies Driving the Smart Utility Revolution

Several key technologies are at the heart of this transformation:

-

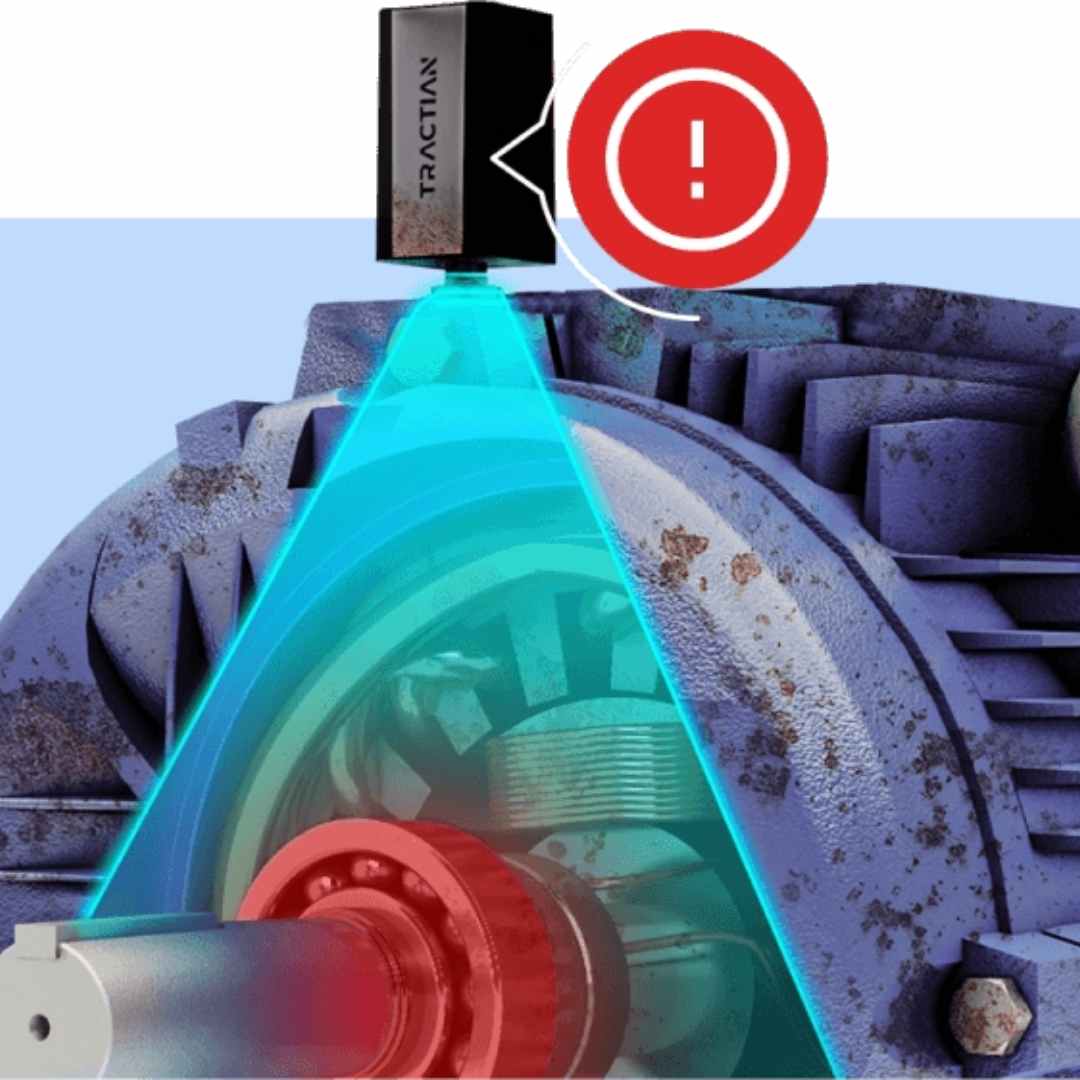

Smart Sensors: These devices are the eyes and ears of the IIoT, collecting real-time data on equipment performance, environmental conditions, and process parameters.

-

Data Analytics: Sophisticated algorithms analyze the vast amounts of data collected by sensors, identifying trends, anomalies, and patterns that would be impossible to detect through manual observation.

-

Cloud Computing: The cloud provides the infrastructure for storing, processing, and analyzing the massive datasets generated by IIoT devices, making data accessible from anywhere, anytime.

-

Predictive Maintenance: Machine learning algorithms leverage historical data and real-time sensor readings to predict equipment failures before they occur, allowing for proactive maintenance and minimizing downtime.

-

Automation: Automated control systems can adjust equipment settings in real-time based on data analysis, optimizing performance and efficiency without the need for constant manual intervention.

Blackhawk Equipment: Embracing the Future of Industrial Utilities

Blackhawk Equipment is committed to helping its customers navigate the complexities of Industry 4.0 and leverage the power of smart technologies for their industrial utilities. We partner with leading technology providers like VPInstruments, integrating their advanced flow meters and monitoring systems into comprehensive solutions tailored to each customer's unique needs. Our team of experts, including our AirMaster+ Specialists, possess the in-depth knowledge to design, implement, and support these cutting-edge systems. We empower our clients with the data-driven insights they need to optimize their operations, reduce costs, and achieve new levels of efficiency.

What are you waiting for? The future is now!

The future of industrial utilities is undeniably smart. Industry 4.0 technologies are paving the way for unprecedented levels of efficiency, reliability, and proactive maintenance. By embracing these advancements, companies can transform their utility systems from cost centers to strategic assets that drive operational excellence. Blackhawk Equipment is your trusted partner on this journey, providing the expertise and solutions needed to unlock the full potential of your industrial utilities.

Ready to explore how smart technologies can benefit your operations? Contact Blackhawk Equipment today to discuss your specific needs and discover how we can help you navigate the exciting landscape of Industry 4.0 and transform your industrial utilities for the future.