Converting Natural Gas Starting System to Air – Cuts Emissions

manages complex retrofit

BY NORM SHADE

With increased focus on greenhouse gas (GHG) emissions, end users are looking at ways to reduce methane gas emissions. Along with carbon dioxide, the Environmental Protection Agency categorizes methane as as a major GHG that contributes to global warming.

Some loss of methane to the at- mosphere is essentially unavoidable without extreme measures. Examples include gas leakage from reciprocating compressor piston rod packing, pipeline and compressor venting re- quired for maintenance or safety, and small leaks from valve stem seals.

Methane emissions associated with the use of natural gas for pneumatic control and power also are a prime target for reduction. Historically, the use of pressurized natural gas for reciprocating engine and gas tur- bine starter motors has been a common practice. Whether at the well- head or on a pipeline, there is usually enough line pressure available to ex pand gas through the starters to get the compression equipment started. This is an effective alternative and is essential for ”black starf’ capability or where insufficient local utility services are available.

Where sufficient electrical power is available, a pressurized air starting system provides a better environmen-tal solution when GHG is a concern. It also reduces operating costs andeliminates the potential safety risk as- sociated with venting large amounts of natural gas "within the fence" of compression facilities.

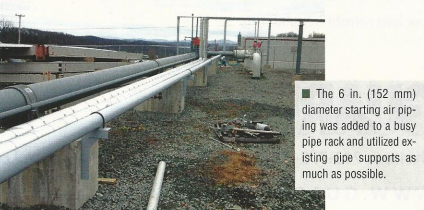

However, designing and installing a suitable air starting system can be a complex project, especially when the system is a retrofit installation. “Set- ting the air receivers and compressors tends to be simpler than routing the pipe from the air compressor building to the units in the main compressor building and revamping the on-skid piping of several different units, which can be quite a challenge,' said Les

Pullig, vice pfesident, engineering for Gas Compression Consultants (GCC). "It requires navigating the new pipe through a busy pipe rack, utiliz- ing existing pipe supports as much as possible, and then integrating it onto the congested engine skids".

The starting air system design be- gins with determining the pneumatic starting motor air (pressure and flow) requirements for the engines at the

specific site. This is influenced by how many units must be started at once and how much time can be tolerated for the air system to pump back up to pressure after a start attempt. This requirement determines the number and size of air compressors and re- ceivers (i.e., storage tanks).

Next, air drying equipment must be sized, electrical requirements deter- mined, space needs defined, place- ment locations chosen, piping sized and routings planned, and plant control system interfacing worked out. In ad- dition to overall project management, the air system design requires civil, electrical and mechanical engineer- ing disciplines. And there is usually a need to work with various government agencies to gain necessary building and environmental permits. Even local electric utilities may get involved, de- pending on the power requirements for the air compressors. Development of instalJation drawings, component pro- curement and selection, and manage- ment of contractors are also important aspects of the project. Finally, start-up and commissioning must be carried out and as-built drawings completed.

A recent GCC pfoject at Williams Midstream's Lathrop Compressor Sta- tion near Tunkhannock, Pennsylvania, is an example of the detail that has to be considered in such a system design.

Cater pillar G3608 and three G3516 gas engines used to drive reciprocat- ing compressors.

Cater pillar G3608 and three G3516 gas engines used to drive reciprocat- ing compressors.

“Not only were GHG emissions reduction and improved safety from elimination of gas venting primary reasons for the conversion to the air start system, the wet gas that was coming into Lathrop would freeze at the skid edge 150 psi (10.3 bar) regu- lator which reduced the pressure from about 700 psig (48 bar) coming into the plant," Pullig said.“

This required adding heat tracing and insulation on all the on-skid start- ing gas lines. Marcellus gas also tends to produce a lot of salts that fouled the starter motors and reduced their per- formance and reliability."

The operators at Lathrop wanted enough air supply to be able to crank two of the G3608 engines simultane- ously for up to two minutes. In addi- tion to supplying air for the Mo-minute start cycles, the receiver volume and compressor capacity were designed to restore the air system to the re- quired starting pressure level within about 12 minutes after a start cycle.

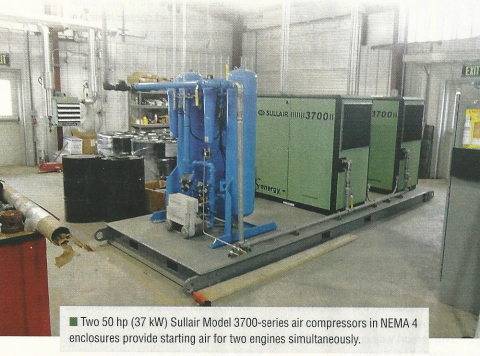

Two 50 hp (37 kW), 460V TEFC motor-driven, oil-flooded Sullair Model 3710 rotary screw air compressors in NEMA 4 electrical enclosures were

selected to provide the starting air. The two compressors were arranged on a single skid built by Blackhawk

Equipment Corp. of Arvada, Colorado, with all necessary PLC controls, in- strumentation, filters, dryers, coolers and drain connections. Each screw compressor delivers 196 scfm (5.55 m"/min) at 150 psig (10.3 bar) dis- charge pressure. They operate at ap- proximately 3665 rpm, driven through a 2.06 gear ratio by electric motors that have 1.2 service factors.

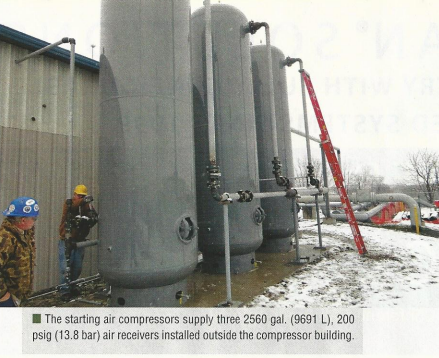

The compressors supply three

2560 gal. (9691 L). 200 psig (13.8 bar) MAWP ASME coded air receivers, measuring 60 in. (1524 mm) diameter by 220 in. (5588 mm) tall, which were installed off-skid and outside the com- pressor building on a new concrete pad. All three receivers are tied into a 6 in. (152 mm) diameter header that was routed on existing pipe racks to the main compressor building. Start- ing air is stored at 175 psig (12.1 bar).

GCC provided all engineering serv- ices required to design, permit, in- stall, start up and commission the complete engine air system. The scope incJuded specifications and procurement of air compressors, fil- ters, dryers, receivers, instrumenta- tion and controls. The company also assisted with the integration of the new equipment into existing facility controls, procedures and the emer- gency shutdown system as well as on-site management and assistance with the system start up and com- missioning. The new system was in- stalled and commissioned last fall.

'Integrating the new piping and con- trols into both the Caterpillar G3516 and G3608 engine skids was a chal- lenge," explained Pullig. "Not only did

we upgrade starter inlet piping from 2 to 3 in. (51 to 76 mm) in only enough space for 2 in. (51 mm) pipe, but we also removed the starter and engine prelube vents from the existing gas units on the skid. We also encoun- tered things like the air header pres- sure being much higher — roughly 10 psig (0.7 bar) higher than the receiver pressure — on hot days due to the sun heating up the gray pipe."

“Our focus is improving the eco- nomic oerformance of compression facilities and gathering systems, from a clean sheet of paper to a revamp of an existing facility and equipment,” said Wayne Sartori, president and founder of Denver, Colorado-based GCC. ”Our expertise and experience in natural gas systems has allowed GCC to provide solutions to our cli- ents for smaJl well head operations to large mainline gas processing and transportation systems." uT2